Listing ID #4217200

Company Information

Ask for more detail from the seller

Contact Supplier

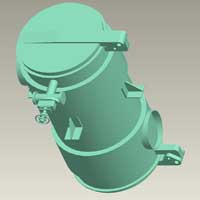

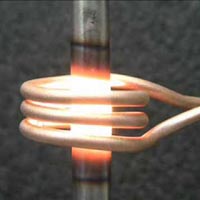

More than 300 Direct Contact Juice Heaters from VRL are in operation with no complaints of any nature. They play major role in the success story of VRL towards Steam Economy.

These Direct Contact Juice Heaters work with very low approach temperature of about 1°C between heating and heated media. This feature allows utilization of low temperature vapors for better use in juice heating.