Listing ID #3912236

Company Information

Ask for more detail from the seller

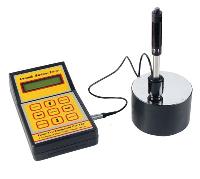

Contact SupplierDigital Hardness Tester for Rockwell Tests has motorized automatic cycle operation i.e. load/dwell/unload. The Preliminary Test Force is 98.07N (10kgf). Total Test Force is 588.4, 980.7, 1471N (60,100,150 kgf). Test Force Selection is by external mechanical dial. The system has bar indication on display for Preload. User can set Preload Dwell time, Dwell time for Total Load and Elastic recovery Dwell time. The operation is easy with keyboard entry through reliable membrane switches for scale/HI-GO-LO/Dwell time selection. The scale display is with 0.1 Rockwell Resolution.

The system has real time measurement with Digital Dial Indicator of 1 micron resolution.

The machine has feature of data export to PC or serial printer. It gives results indicating serial number of tests, hardness scale, hardness value and high / good / low indication w.r.t limits entered.

The Digital Rockwell Hardness Tester (MCS-RASNE) covers Rockwell scale A, B, C, D, E, F, G, H, K, L, M, P, R, S, V and confirms IS : 3804, BS 10109-2 & ASTM E-18. The Digital Rockwell Superficial Hardness Tester (MCS-RASNE/S) includes all Rockwell scales and 15T, 30T, 45T, 15N, 30N, 45N, 15W, 30W, 45W, 15X, 30X, 45X, 15Y, 30Y, 45Y and confirms IS : 5073, BS 10189-2 & ASTM E-18

Also Available is

MCS-RASE - Basic Rockwell Machine with digital readout interface with all above features except manual load/unload cycle. MCS-RASE/S - MCS-RASE with Superficial Hardness Tester scales

Optional Accessories

• External serial thermal printer to print reports

• PC software to interface machine to computer

Principle :

Rockwell & Rockwell superficial tests consist of forcing an indentor (Diamond or Ball) into the surface of a test piece in two steps i.e. first with preliminary test force and thereafter with additional test force and then measuring depth of indentation after removal of additional test force (Remaining preliminary test force active) for measurement of Hardness Value.

Brinell test consists of forcing a hardened ball into surface of a test piece with a specified test-force and measuring the diameter of indentation for evaluation of Brinell Hardness number.

Operation :

For Rockwell & Rockwell superficial Test :

In case of 'RASN' series machines for Rockwell or Rockwell superficial tests, a preliminary test force is first applied without removing zero Quickly thereafter an additional test force is applied without removing the preliminary test force. When the penetration is stabilised, the additional test force is removed and the hardness number is shown directly on the indicator.

For Brinell Test :

The operation is exactly same as above. However, the diameter of impression is measured out side of machine by Brinell microscope. Brinell hardness number is found out by refering corresponding hardness tables showing hardness number against dia of indentation for specified ball diameter and test force.