Listing ID #4228974

Company Information

Ask for more detail from the seller

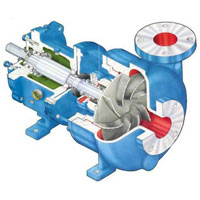

Contact SupplierDiaphragm Pumps are recommended for hazardous, Toxic and Poisonous liquids, where leakage is not at all permitted. Diaphragm pumps have hydraulically actuated diaphragm and a back pressure valve. The main function of back pressure valve is to balance the hydraulic oil in the chamber. The reciprocating plunger transmit displacement through hydraulic oil to the diaphragm, the oscillation of diaphragm produces pumping action on process fluid with help of Non-Return Valve in built at both ends. The diaphragm acts as a perfect seal between the hydraulic oil and the liquid being pumped. Diaphragm pump can be provided with single or double diaphragm; usually Teflon acts as a diaphragm. The back pressure valve which is in the hydraulic oil tank ensures pumping accuracies for long period. The pressure drop in hydraulic chamber due to oil leakage is automatically compensated by opening back pressure valve. Besides back pressure valve acts as safe guard from damages if discharge pressure exceeds pump rated pressure.

Range of Capacity - ‘DENCIL’ Brand diaphragm Pump is available for 0.5 Ltrs to 12,000 Litres per hour and pressure up to 100 Kg/cm2 in various model to suits client application.

DENCIL offers :

Design feature/benefits of diaphragm pumps

Design Facilities & Manufacturing Standrads

Tests performed on each pump

Applications