Listing ID #4126711

Company Information

Ask for more detail from the seller

Contact SupplierAir-operated double diaphragm pumps can move anything from fine chemicals (gentle, non-shearing action), to abrasive and viscous slurries (no close-fitting parts, low internal velocities), and almost any other product that can move. A few of the thousands of products now being pumped:

1.Paints & solvents

2.Pigments

3.Resins

4.Construction water & waste

5. &

6.Mine tailings

7.Chemicals

8.Oils & lubricants

9.Glues & adhesives

10.Dyes

11.Foods

12.Tanker loading/unloading

13.Marine barges

14.Ceramic slips, slurries & glazes

15.Latex

16.Driller's mud

17.Inks & printing liquors

18.Against filter press

19.Low density powders

20.Handling Barrels, Jerry Cans, Carboys.

Versatile Performance

1.Can run dry indefinitely without damage.

2.No shaft seals or gland packing.

3.Infinitely variable flow & discharge pressure from 0 to pump's maximum by adjusting air pressure.

4.Gentle non-shearing action.

5.If discharge is clogged or closed pump stops immediately; no power consumed, no heat, no wear. By opening discharge, flow starts automatically.

6.Operates submerged or with flooded suction.

7.Self-priming from a dry start.

8.Pressures up to 100 PSI (7 bar).

9.No close fit, sliding or rotating parts. Low internal velocity reduces wear.

10.Quick assembly/disassembly with split clamp bands.

11.Capable of pumping at high temperatures.

12.Quiet, steady discharge flow without use of pulsation dampener.

13.Safe for use in explosive environments. No electrical hazards or costly motor and control equipment needed.

14.No pressure relief or bypass piping required because pump pressure never exceeds air inlet pressure.

15.Pollution-free operation. The pump even improves air environment in confined areas.

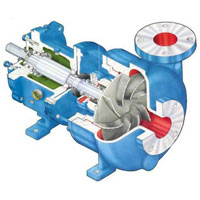

The air valve directs pressurized air to the back side of diaphragm 1. The compressed air is applied directly to the liquid column separately by elastomeric diaphragms. The diaphragm acts as a separation membrane between the compressed air and the liquid. Driving the diaphragm with air instead of the shaft balances the load and removes mechanical stress from the diaphragm, dramatically extending diaphragm life. The compressed air moves the diaphragm away from the center block of the pump.

The opposite diaphragm is pulled in by the shaft connected to the pressurized diaphragm. Diaphragm 2 is now on its air exhaust stroke; air behind the diaphragm has been forced out to atmosphere through the exhaust port of the pump. The movement of diaphragm 2 toward the center block of the pump creates a vacuum within chamber 2. Atmospheric pressure forces fluid into the inlet manifold forcing the inlet valve ball off its seat. Liquid is free to move past the inlet valve ball and fill the liquid chamber.

The heart of the Double Acting Air Operated Diaphragm Pump is the air valve which shifts the air supply to both diaphragms alternately with complete reliability under all conditions of head and flow. The air valve performs this function with a simplicity in design and serviceability.

Material of construction PolypropyleneCast Iron

Cast Aluminium

S. S. 316

Teflon (PTFE)

Neoprene / EPDM / Nitrile / PTFE / Hypalon

Accessories:1) F.R.L : Air Filter, Regulator and Lubricator are required in Air line to provide clean, moist free air at constant pressure to the pump. FRL also helps to lubricate air valve assembly (connecting shaft and piston).

2) Needle valve in brass.

Size available 1/4", 3/8", 1/2".