Listing ID #4056005

Company Information

Ask for more detail from the seller

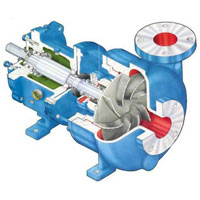

Contact SupplierAir-operated double diaphragm pumps can move anything from fine chemicals (gentle, non-shearing action), to abrasive and viscous slurries (no close-fitting parts, low internal velocities), and almost any other product that can move.

Versatile Performance

Air Operated Double Diaphragm Pumps

| POLYPROPYLENE | AOD - 20 | AOD - 25 | AOD - 50 |

| HEIGHT : (in mm) | 410 | 635 | 787 |

| WIDTH : (in mm) | 215 | 406 | 483 |

| DEPTH :(in mm) | 280 | 304 | 368 |

| WEIGHT : (in kg.) | 9.5 | 18 | 30 |

| AIR INLET : (in BSP) | 1/4" | 3/8" | 1/2" |

| SUCTION : (in mm) | 25 | 40 | 50 |

| DISCHARGE : (in mm) | 25 | 40 | 50 |

| SUCTION LIFT : (in m.) | 3 | 3 | 4 |

| Max. Solid Size. (in mm) | 5 | 10 | 15 |