Listing ID #6979685

Company Information

Ask for more detail from the seller

Contact SupplierDIAMOND PULLEY LAGGING

TROUGHED PULLEY CONVEYORS

PULLEY LAGGING

INTRODUCTION

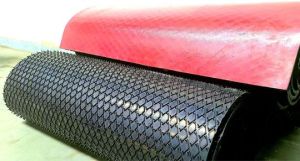

Lagging is the term used to describe the application of a coating, cover or wearing surface which is sometimes applied to pulley shells.

Lagging is often applied in order to extend the life of the shell by providing a replaceable wearing surface or to improve the friction between the belt and the pulley. Notably drive pulleys are often rubber lagged for exactly this reason.

This section provides some useful information regarding the different types of lagging as well as some technical details and recommendations for lagging of pulleys.

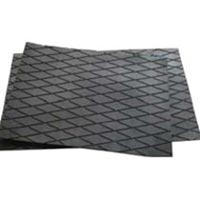

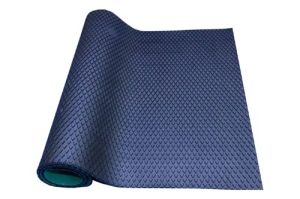

DIAMOND PULLEY LEGGING

Rubber lagging is applied to pulley shells in order to improve the friction between the pulley and the belt.

Conveyor drive pulleys are often supplied with diamond grooved lagging as indicated in the adjacent sketch.

‘Diamond grooved lagging’ refers to the pattern in the lagging and this pattern, like with vehicle tyres, enhances the grip or friction even if the belt surface is dirty.

Conveyor Technology has accumulated more than a decade of experience in research and development, manufacturing, and marketing of conveyor belting for various industries such as mining, steel, power plants, and more. Today, Conveyor Technology is emerging as a leading domestic provider of Conveyor Belting Products and Services.

The company prides itself on its ability to innovate, design products, and apply engineering solutions. In addition to striving for the highest technical standards, we are guided by core human values. At CT, we consider our customers as partners and value their opinions on quality. Our unwavering commitment to customer service and human safety remains sacred. It is the combination of these factors that is propelling us to become leaders in conveyor systems.

Given the challenging operating conditions that conveyors face, it is of paramount importance to choose the right belt that can withstand impact, ripping, abrasion, bacteria, acid, and water, and ensure trouble-free operation over its lifespan. With our stringent quality checks and state-of-the-art conveyor belting facilities, CT's conveyor belts are competent, dependable, and safe, ensuring profitable operations.

Our Mission:

Conveyor Technology aims to become one of the leading solution providers in the Material Handling sector. CT is uniquely positioned with extensive resources for manufacturing, supplying, servicing, and engineering specialized products, all consolidated under one roof.

Our Vision:

Our management team envisions CT as a global leader in the Conveyor Components industry, capitalizing on both international and domestic markets. We strive to achieve total customer satisfaction through continuous research and development, fostering innovation, and consistently delivering superior products. Our company's complete focus is on prompt deliveries, customer satisfaction through quality, after-sales support, and services.