Listing ID #2050136

Company Information

Ask for more detail from the seller

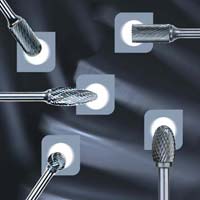

Contact SupplierWe are specialized in the manufacturing of Deburring Tools, which are much acclaimed for their robust construction, unique design, Tungsten Carbide coating which makes the tools and the blades highly stable under the most rigorous cutting conditions. We are also engaged in manufacturing products like Deburring Tools, Hole Deburring Tools and more. These DeburringTools are tough and strong to hold in any given situation. Avail this durable range of eburring Tools at competitive prices.

Operation & Advantages

Bottom Side of a drilled hole is deburred or chamferedDeburring & Chamfering tool deburrs are Automatic & Dual Purpose, chamfers a drilled hole at both side when the tool passes through and reverses.There is no change either in the spindle speed and in the direction of spindle rotation or in the job set-upTools can be easily deployed immediately after drillingManual interruption & special operational skills are not required at any stage of useFew seconds are require both purpose deburring and chamferingThe Chamfers are uniform & concentric to the bore

Construction & Mechanism Of Deburring Tools

Deburring tool comprises of 4 parts that is Shank, HSS Blade, Fulcrum Pin and Screw for adjusting blade projectionThe blade is manufactured of HSS and that is coated with Tungsten Carbide helping in wear resistanceDeburring and chamfering is done on the top surface of a hole, blade retracts into the pocket in the tool shank and the cutting pressure increases the blade which gets released from the pocket when cutting pressure reduces and then the deburring and chamfering operations are executed on bottom of the holeCare is taken to ensure that tool or its parts do not damage the boreHolding Shank is cylindrical in shape to ensure tools can be mounted on the machine spindle easily through a drill check or a colletWhen cutting edges get blunt the blades can be re sharpen

Available In

Standard tools are available in sizes from diameter 5 mm to 30 mm