Listing ID #3387501

Company Information

Ask for more detail from the seller

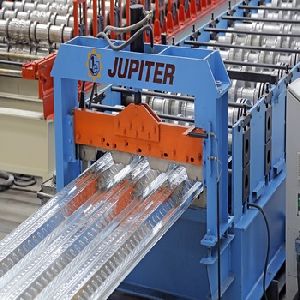

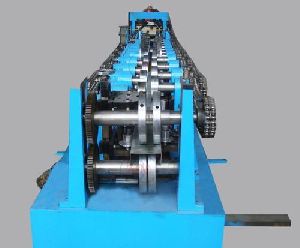

Contact SupplierRoll forming, also spelled roll forming, is a type of rolling involving the continuous bending of a long strip of sheet metal (typically coiled steel) into a desired cross-section. The strip passed through sets of rolls mounted on consecutive stands, each set performing only an incremental part of the bend, until the desired cross-section (profile) is obtained.

Roll forming is ideal for producing parts with long lengths or in large quantities. It can also produce parts of multiple lengths from the same tooling. Virtually any material that can be formed using sheet forming techniques can also be roll formed. Roll forming may also be an excellent solution whenever consistency of the cross-sectional profile is critical.