Listing ID #4646368

Company Information

Ask for more detail from the seller

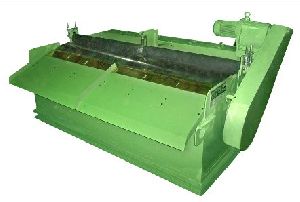

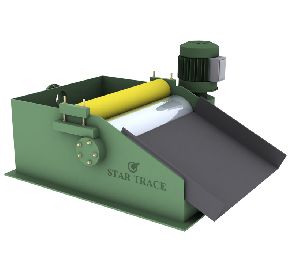

Contact SupplierHoning is a very material removal process used to generate better surface finish on components. If proper filtration is not provided these particles escape the filtration system and generate scratch marks on the surface deteriorating the Ra and Rz values.

A CFS for Honing process is sized based on grit size, viscosity of fluid and material of component. As the viscosity increases or the grit size becomes finer, the flow velocity through filter media has to be reduced to achieve desired results.

Dirty fluid alongwith grinding muck falls into the vacuum filter. Dirt cake is generated on the filter media ( check the actual working ). Clean fluid is directly pumped to next stage of filtration system. In this stage either a backwashable candle filter or precoat filter is used based on the process requirement. These filters generate a filtration level of 1 micron.

The filtered fluid is stored in tanks from where a different set of pumps delivers it to your machines.If the muck generation is very low, the first stage filtration of vacuum filter is eliminated and only the finer filters are used.

Features & Benefits