Listing ID #3904269

Company Information

Ask for more detail from the seller

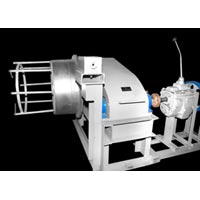

Contact SupplierGeneral Features:

- Main body with base, drawing drum and drawing die box of close grain Cast Iron

- Water Cooling arrangement provided inside the Drawing Drum and the Die Box

- Phosphorous bronze gears with high carbon axle steel worms

- Suitable for making Nail Wire from 8 mm or 6 mm input rods up to 2 mm

- Also suitable for making Wire used to make Barbed Wire, Wire Mesh, etc.

- Wet / Slip type Fine Wire Drawing Machine also available - Details on request.

The wire rod to be drawn is pointed in the Wire Pointing Machine. This pointed wire is inserted through the die of the first Wire Drawing Machine and fastened to a locking device on the drum. The drum is then started. As the drum rotates, the wire fastened to the drum gets pulled and coiled around the drum. Since the wire getting pulled is passed through the die having a higher inlet diameter and a lower outlet diameter, the drawn wire diameter gets reduced.

The starting end of the drawn wire is released from the lock of the first drum, is passed through the overhead loop and pulley provided, is brought down and is inserted through the die of the second drum and drawn through this die for further reduction. Thus, the wire is drawn through all the wire drawing drums of the set in a continuous manner to get the required finished diameter of the wire.

When the drum of the last wire drawing machine gets fully loaded with the drawn wire, the machine will be stopped to unload the finished material and then restarted. (If one opts for the continuous coiling machine, the drawing process will not have to be stopped for this purpose)

When the bundle of input rod finishes, the machine should be stopped. The end of this bundle is welded to the end of a new bundle of rod using the butt welding machine. Then the process is to be continued.

Also, in case of an accidental snapping of wire in between drums, the snapped ends are welded with the help of the butt welding machine and the process is continued.

| Model: | WD-750 | WD-610 | WD-560 | WD-460 | WD-305 | |

| No. of Blocks: | 1 to 3 | 1 to 6 | 1 to 8 | 1 to 6 | 1 to 10 | |

| Diameter of Drum: | 750 mm (30") | 610 (24") | 560 (22") | 460 (18") | 305 (12") | |

| Material to be Drawn: | Mild Steel / High Carbon Steel / Non-Ferrous Metals | |||||

| Inlet Wire Size (mm): | 12 | 8 | 6 | 4 | 2.6 | |

| Finished Wire size (mm): | 6 | 3.37 | 2 | 1.68 | 0.7 | |

| Finishing Speed (Machine rpm): | 45 | 110 | 140 | 180 | 380 / 540 | |

| Motor (HP): | 1st Block: | 50 | 40 | 30 | 15 | 10 |

| 2nd Block: | 40 | 30 | 25 | 10 | 7.5 | |

| 3rd Block: | 30 | 25 | 10 | 10 | 7.5 | |

| Rest of the Blocks: | -- | 20 | 10 | 10 | 5 | |

| Approximate Block Weight (kgs.): | 1850 | 1550 | 1450 | 800 | 500 | |