Listing ID #4153490

Company Information

Ask for more detail from the seller

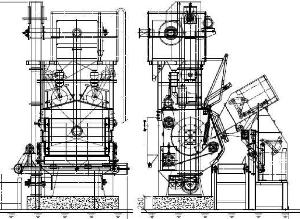

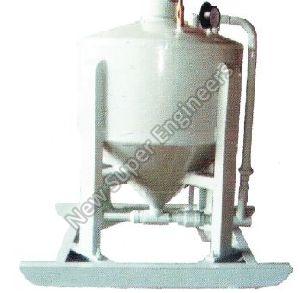

Contact SupplierThe machine works on pressure blasting principle, consist of Dual (two) Blast generator cum storage tank for continuous operation. The unit have upper and lower blast generator (pressure vessel). The abrasive, after blasting is transferred to upper blast chamber. When lower blast chamber is pressurized, the mushroom valve of upper blast chamber opens to receive the abrasive and store it. After fix time interval the mushroom valve of upper blast chamber get closed and mushroom valve of lower blast chamber gets open. At this time the abrasives get transferred to lower generator, without interfering the blasting process. Hence this dual chamber machine works continuously. The blast generators is fabricated from 6mm Ms Sheet as per IS-2825 and hydraulically tested for 250 psi.

Underneath the blast generator, the specially designed pneumatically controlled grit valves is provided for independent control of blasting nozzle. The mixing tube at the bottom of grit valve mixes the abrasive with compressed air to carries the abrasive to the blasting nozzle for blasting.

A vibratory screen (operated by compressed air) has provided at the top of upper pressure chamber so that the incoming abrasive get screened for over size particles and debris before entering the upper blast chamber. Above the screen a cover is provided which have provision for connecting it to incoming line of abrasives.