Listing ID #4109061

Company Information

Ask for more detail from the seller

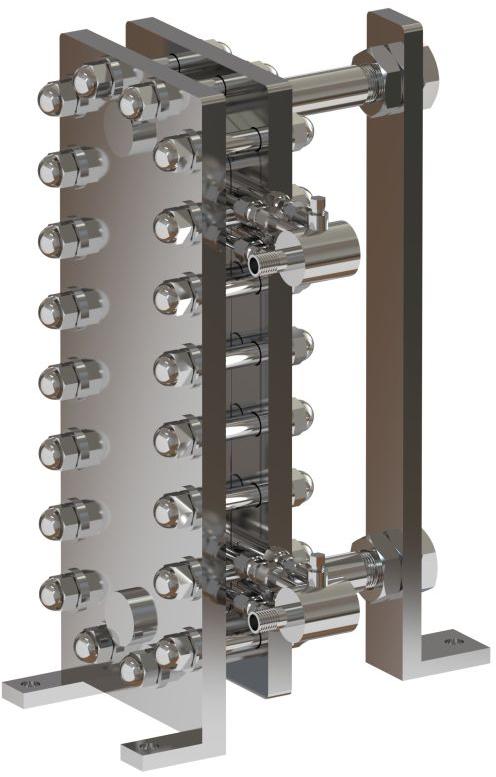

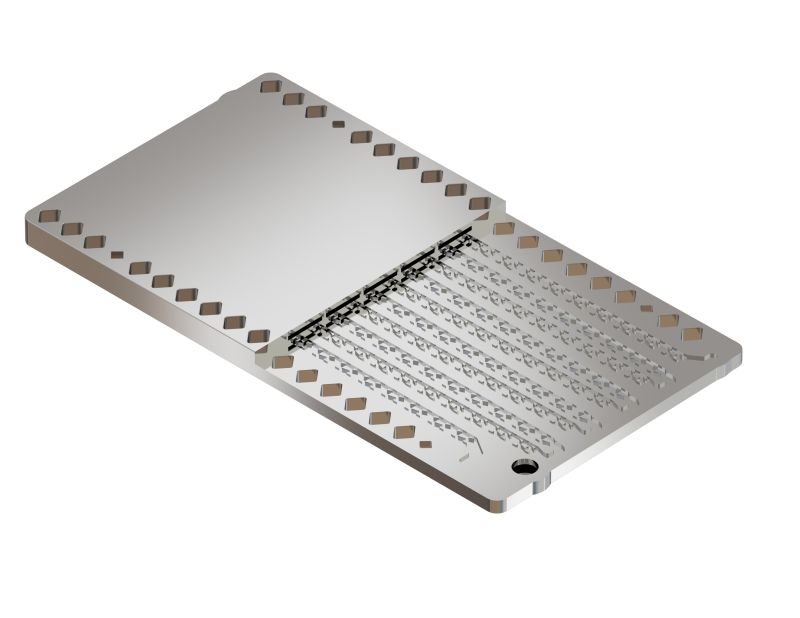

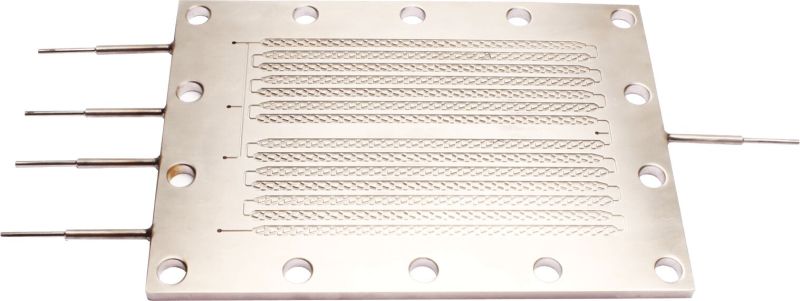

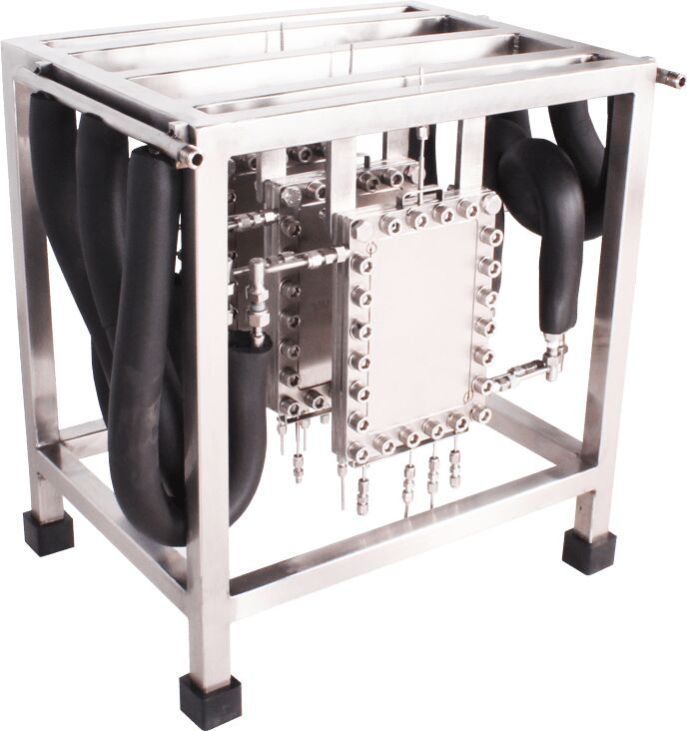

Contact SupplierAMaR series is ideal for carrying out a wide range of chemical reactions in the field of pharmaceuticals, fine and specialty chemicals in a continuous manner.

Suitable for