Listing ID #4270584

Company Information

Ask for more detail from the seller

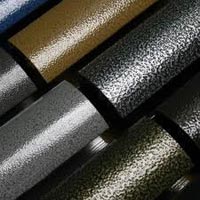

Contact SupplierAcrylic Modified Emulsion & Waterproof Additive For Mortar & Concrete Dubond’s Hydro Crete is an acrylic emulsion which when added to cement mortar / concrete / grout provides good adhesion, water resistance and improvement of other properties. It is available in form of a milky liquid.

Areas of Application

Features & Benefits

Method of Application

Concrete surfaces should be sound and clean, free from oil, grease, cement laitance & loosely adhering particles. Absorbent surfaces should be saturated thoroughly with water but without showing any puddle on their surfaces

Application Instructions

Mixing : Mixing of diluted Hydro Crete to cement mortar / concrete should preferably be done manually. When a concrete mixer is used, pour the mortar as soon as its consistency is cohesive. Do not run the mixer too long.

Application Instructions

Aggregates

Aggregates used in the mortar / concrete should be well graded and thoroughly washed. Sand particles sizes should correspond to the thickness of mortar to be applied.

Application Method / Tools

Shelf Life & Storage

12 months from date of production if stored in undamaged & unopened, original sealed packaging, in dry conditions & protected from direct sunlight. Protect from frost.

(Mpa) Hydro Crete by weight of cement (According to ASTM C 109)

| Curing Time | Control | 5% | 10% | 15% |

| 7 Days | ~30 N/mm2 | ~20 N/mm2 | ~25 N/mm2 | ~29 N/mm2 |

| 28 Days | ~50 N/mm2 | ~35 N/mm2 | ~38 N/mm2 | ~44 N/mm2 |

| (Mpa) Hydro Crete by weight of cement (According to ASTM C 293 -79) | ||||

| Curing Time | Control | 5% | 10% | 15% |

| 7 Days | ~7 N/mm2 | ~8 N/mm2 | ~8.5 N/mm2 | ~8.9 N/mm2 |

| 28 Days | ~9.5 N/mm2 | ~10 N/mm2 | ~10.5 N/mm2 | ~11.8 N/mm2 |

Hydro Crete by weight of cement

| Control | 5% | 10% | 15% |

| ~5.9% | ~2.9% | ~2.0% | ~1.60% |