Listing ID #3915790

Company Information

Ask for more detail from the seller

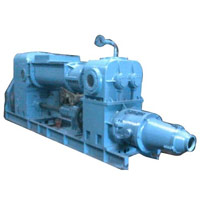

Contact SupplierThe colloid mill is suitable for cutting down the particle size of a solid or liquid suspended in a liquid. Equipped with hydraulic shear, the colloid mill machine is widely used for creating particles of same size, dispersing, mixing of materials. The colloidal machine has found its wide usage in industries including food & beverages, pharmaceutical, suspensions & emulsion, cosmetics and more. The colloid mill machinery involves stator and rotor in the cylindrical vessels to do shearing for reducing the material size.

Working Principle:The material to be reduced enters the colloidal mill through its inlet hopper. It then passes through the gap created between the rotor and stator. The mill then cuts down the size of the material to the desired level. The process requires the inclusion of heavy liquid to start the shearing process. During the milling process, both the materials are stirred at a high rate while the processed material starts draining out of the outlet. If required, the process can be repeated through its re-circulating pipe assembly.

Salient Features:

| MODEL | DTCM - 250 | DTCM -500 | DTCM-1000 |

|---|---|---|---|

| Output - Litre / Hour | 150 to 1500 | 150 to 2500 | 250 to 5000 |

| Drive type Option | Vertical OR Horizontal | Vertical OR Horizontal | Vertical OR Horizontal |

| Rotor Speed- RPM | 2800 | 2800 | 2800 |

| Hopper Capacity- Litre | 15 Litre | 15 Litre | 25 Litre |

| Seal Type | Rubber Silicon | Rubber Silicon | Mechanical |

| Partial Size Reduction- Micron | 5 to 10 | 5 to 10 | 5 to 10 |

| Electric Motor H.P. | 3 | 5 | 10 |