Listing ID #3908349

Company Information

Ask for more detail from the seller

Contact SupplierThe panels should be stored in the area where they are not susceptible to damage. Panels are to be stored at leveled surface. When stored in open places without shed, provide spacers at regular intervals and place panels above that. Cover the stack panels with tarpaulin to avoid sunlight.

WALL PANEL INSTALLATION:

• On the leveled floor, fix the “C” channel on the floor.

• Place the panels on the fixed channel as per their specified location.

• Note while placing the panels that the notches are at the top to place the ceiling panels.

• Tighten the cam locks between the panels which are placed through the length of panel. The lock and pin are located inside the PUF panels. An 8mm Allen key is required to tighten the cam lock. The cam lock must first be set by inserting the Allen key into the cam lock hole which is pre-drilled and turning anti clockwise until the resistance is felt. Now the two panels can be locked together by butting and turning the Allen key in clockwise direction until the two panels are securely drawn and locked.

• Cut outs for doors and windows or for any other purpose can be made on site. The bare exposed part can be covered using “C” channel Flashing.

FLOOR INSULATION:

• A vapor barrier is laid over the reinforced concrete floor slab.

• Joints in the vapor barrier should be sealed as the barrier also acts as the vapor control layer.

• Puf slabs should be laid tightly-butt jointed or stagger joints should be made for multi layer insulation as per required thickness.

• The reinforced concrete finished slab can then be placed on the top.

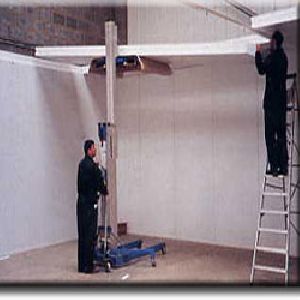

CEILING PANEL INSTALLATION:

As per the installation drawing, place the ceiling panels in position on the notch of the wall panels. Place the adjoining panels and align the panels. Ensure proper locking. If the panels are not leveled at the top, the ceiling panels will not butt properly and gaps will result. The level must be corrected immediately. In case of large storage areas, the ceiling panels have to be supported by the frame. The ceiling support system will vary from project to project.

BEAM AND COLUMN INSULATION:

There are two methods of insulation of beams and columns:

• Conventional Method:

In this method puf sheets of desired thickness are applied on the beams and the columns and G.I. cladding is later done over the applied sheets.

• Applying sandwich panels (Modern Method):

We provide cut size puf insulated panels with one side G.I. sheet and other side paper which is made as per the dimensions of the beam or the column. These panels can directly be erected to get joint free insulation within no time.

After the completion, at the internal and external corners “L” channels must be riveted to seal the gaps. The pop rivets should be riveted at appropriate distance. Silicon sealant application must be done properly to cover any possible gaps.

In case on low temperatures to be maintained, we provide special flashings through which polyurethane foam is injected to seal up all the gaps left between the joints like flooring to wall, corners, wall to ceiling to avoid any chance for the transfer of temperature due to which losses occur. It is also helpful to avoid heat bridges.

"WE FOLLOW IS:12436-1988 FOR PREFORMED RIGID POLYURETHANE (PUR) AND POLYISOCYANURATE (PIR) FOAMS FOR THERMAL INSULATION."