Listing ID #4199417

Company Information

Ask for more detail from the seller

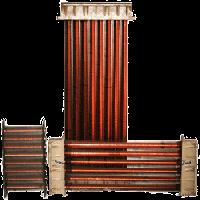

Contact SupplierCoil Type Heat Exchanger is nothing but Copper tubes are artificial to special requirements as to dimensional tolerances, finish and tempers for use in condensers and heat exchangers. These copper heat exchanger tubes are normally supplied in straight length in annealed & half hard temper. The copper tubes shaped by are metal industries not only have the stiff tolerances but also have the most dependable dimensions throughout the tube length. The tube surface is clean both inside and outside with no caustic stains. The copper tubes produced by are metal industries are suitable to transfer heat in a wide variety of operating conditions and to refuse to accept decay for the longest period of time possible under the harshest operating circumstances.Coil type exchangers are more efficient than shell and tube exchangers for low flow rates. Due to their simple construction they are low in price and easy to clean on the shell side. Their thermal efficiency approximates that of a true countercurrent flow type exchanger. Condenserors are used for condensation of vapours and cooling of liquids. Condensers are made by fusing number of parallel coils in a glass shell. Coils are made in different diameters using tubes of different bores.

Specifications :