Company Information

Ask for more detail from the seller

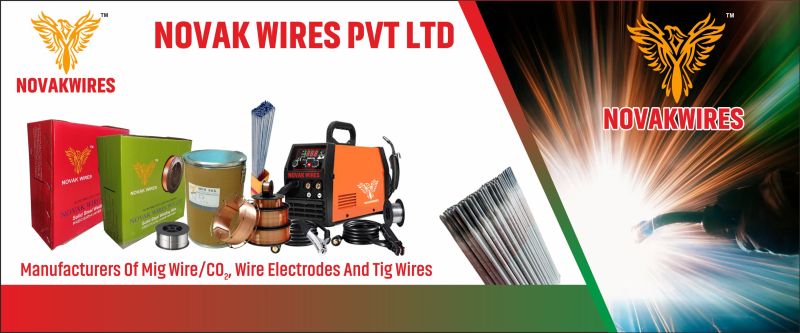

Contact SupplierMIG wire, also known as Metal Inert Gas wire or Gas Metal Arc Welding (GMAW) wire, is a type of consumable welding electrode used in the MIG welding process. MIG welding is a popular welding technique that involves the use of an electric arc to melt and join metals together. Here’s some key information about MIG wire: