Listing ID #3904160

Company Information

Ask for more detail from the seller

Contact SupplierPure Steam (Clean Steam) is a purest form of available steam whose condensate should meet all the parameters of Water for Injection (WFI). In general terms it is defined as the steam which is free from all chemicals & biological impurities.

Application –

• WFI System sterilization

• Fermenter sterilization

• CIP/SIP system condensate drainage

• Sterilization of process vessels and pipes

• Culinary systems

• Humidifiers

• Steam barriers (Blocks & Bleed System)

Applicable Codes – ASME BPE

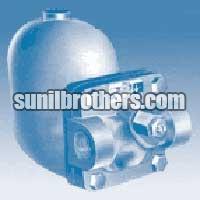

The Uni Klinger make Sanitary steam trap is of balanced pressure design with SS316L bellows capable of releasing condensate within 1̇°C (2 – 3 °F) of saturated pressure. Clean steam Trap utilizes hygienic body clamp allowing disassembly for inspection or cleaning and is made up of entirely self draining design leading to no condensate retention.