Company Information

Ask for more detail from the seller

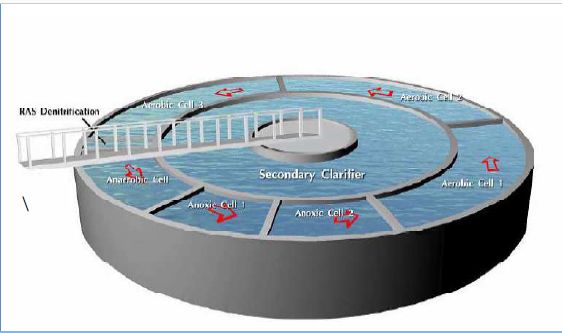

Contact SupplierWe manufacture both varieties: Peripheral and Centrally Driven Clarifiers. Our Yashwant Clarifiers are made from Single Internal Spur Gear with Cyclo Gearbox Drive to reduce power and maintenance requirements. Yashwant Clarifiers are easy to install and provide years of hassle-free and un-interrupted service to our clients. Our design is robust and indigenous, with easily replaceable spares and top-notch after sales and maintenance services.

Our clarifiers have been installed in Industrial and Municipal Sewage Treatment Plants throughout India and up to Tank Diameters as large as 40 Meters. Our Centrally Driven Clarifier has at its heart a1200mm Diameter Spur Gear which provides prolonged service without breakdown and interruptions.

The clarifier tanks can be classified in two groups: Mechanized and Un-mechanized

Early torque ratings were based on the Lewis Beam formula, a criteria that considered tooth strength only. In the 1970's, specifications began to appear requiring that spur gear ratings be based upon AGMA standards, at that time AGMA 210 and 220 for spur gearing, and AGMA 440 for worm gearing. AGMA 210 brought durability into the rating equation. Since that time, AGMA 210 and 220 were combined into new standard AGMA 218, and later into ANSI/AGMA 2001. AGMA 440 evolved into ANSI/AGMA 6034. Throughout the evolution of Clarifiers throughout India, our gear drives have consistently evolved incorporating the best design practices and indigenous designs and concepts. Only suppliers such as us who have kept current with, and reacted to, the changing standards can truly state that their gear drives are "Designed in full conformance with required standards."

Technical Specifications:

Size Range

Types

Torque Limiters - We also provide Torque Limiters (Optional Variant) for monitoring the torque requirements of the Clarifiers with alarm facility in case of excessive torque being subjected on the clarifier drive.

Bridges & Structural Their Designing