Listing ID #258571

Company Information

Ask for more detail from the seller

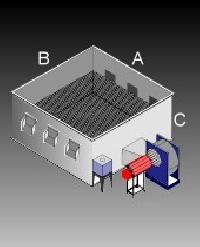

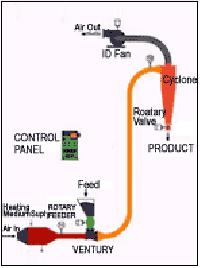

Contact Supplierwe are offering chip board dryer we are well-reckoned chip board dryer manufacturer, exporter and supplier. the chip board dryer is manufactured from high-grade components that are procured from trusted vendors. our chip board dryer has high durability, performance and resistivity to wear & tear. moreover, the chip board dryer has powerful drying performance and sturdy construction. owing to these factors, the chip board dryer is high on demand in the market. dryer capacity material

| Dryer Capacity | 350 to 1000 sheets 8' x 4' per day |

|---|---|

| Wood Moisture | 45% |

| Bagasse Moisture | 50% to 54% |

| Required outlet Moisture | 3% to 4% |

| Feed Rate (kg/s) Wet Material | 1.02 |

| Oven dry material(Kg/s) | 0.770 |

| Products Flow Rate | - |

| Dry Temperature ( | 90 - 100 |

| Efficiency MJ/Kg Residential Time | 20 to 30 Minutes |