Listing ID #4257816

Company Information

Ask for more detail from the seller

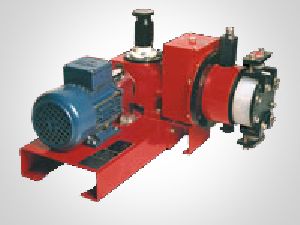

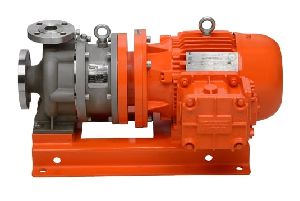

Contact SupplierPVDF Heavy-Duty Process Pumps

The Applications in Chemical Processing Industry.

Process Plant Construction in Demanding Environment

CHEMICAL

PAPER AND PULP

PHARMACEUTICAL

FOOD PROCESSING

NUCLEAR

CHEMICAL INDUSTRY APPLICTIONS IN CHEMICAL PROCESSING INDUSTRY

Acids (Sulphuric, Hydrochloric) Solvents, Oxidising agents

PAPER AND PULPBleaching agents, Chlorine, as, Hydrochloric acid.

PHARMACEUTICAL INDUSTRY (BIOMEDICAL, MEDICINE)High purity, No surface deposits, Inocutty.

FOOD PROCESSING (AGRO ALIMENTARY)Non Leaching, High purity, No surface deposits, Acids(non staining)

NUCLEAR INDUSTRYLong life time, Resistance to Ionizing Radiation, Chemical Resistance to Fluorides

APPLICATIONS IN CORROSION PROTECTION

Chlorine using industryTIO2 PIGMENTS, EPOXY, PHOSGENCE(PC) INTERMEDIATES FOR PHARMA AND PHYTOSANITARY,BLEACHING,HALOGENATED SOLVENTS AND AROMATICS.

BROMINE USING INDUSTRYINTERMEDIATES FOR PHARMA AND PHYTOSANITARY, FLAME RETARDING AGENTS

HOT MINERAL ACIDSOMNIPRESENT TO CATALISE ALL TYPES OF CHEMICAL REACTIONS VERY OFTEN MIXTURES WITH SOLVENTS AND AROMATICS.

The development of PVDF pumps is based on long term experience.The components were designed to supply with more operational safety.The robust design of the bearing housing ensures the smooth running of the shaft and increases the life of mechanical shaft seal

The shaft is so designed to meet the international standards for heavy loads i.e., against open discharge valve, minimum flow rates, maximum impeller diameters and high density.

The heavy shaft design has a very low deflection and avoids the damage to the rotating parts of the mechanical seal

The wetted parts are made up of PVDF permit applications with all aggeressive, corrosive or toxic media by means of their sturdy design with solid PVDF housing completely encapsulated in an outer metal housing they combine the chemical and thermal resistance of the linear material with the mechanical strength of the outer metal casing

CASING LINER AND BACKPLANE.

Thick walled casing liner and back plate is made of PVDF.

Replaceble casing liner completely encapsulated in the metal casing.The pipe line forces are absorbed by the metal casing suitable for high system pressures.

Casing liner and back plate are solid injection moulded with PVDF.

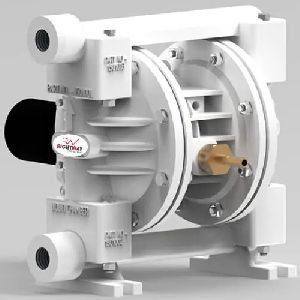

Low MaintenanceIMPELLER

Semi-open impeller.A large metal insert in the PVDF impeller greatly increases mechanical strength

SHAFT SLEEVE

Design is matched to the shaft seal mounting High Alumina Ceramic,Hastalloy B/C, Titanium.

SHAFT SEAL

Single Mechanical Shaft seal of various systems & makes are available

BEARING HOUSING

Rigid shaft made of ss-$10.Double raw bearings with extremely high load capacity on both idle and drive end of the housing.Long life Oil Lubricated bearings on both the sides.

GASKETS

All sealing gaskets are made of PTFE.

TEMPERATURE RANGES

Since the PVDF casing is a lining component encapsulated inside the metal casing the pump with stands a very high range of temperatures without distorsion or any other mechanical stresses.

PUMP CASING LINER AND SHELL.

The figure gives the complete idea about the liner encapsulated in the casing.The roubust casing absorbs all the loads in the system and from the suction

PERFORMANCE RANGE

Flow rate upto 200 m3 /hr.Head upto 80 mtrs liquid column.Pump size are in accordance with ISO/DIN standards enable economical spare parts stocking.