Listing ID #4862934

Company Information

Ask for more detail from the seller

Contact SupplierModel EM-wind is an ideal choice for high output high speed tape-stretching lines for manufacturing of PP/HDPE tapes in the form of cylindrical cross wound packages on steel/aluminum core tubes for the mentioned specifications to be used on circular weaving machines.

This is an inverter driven cheese winder designed to deliver high outputs at minimum running costs for all varieties of tapes. The simplified mechanical construction with minimum moving parts makes it a low maintenance machine. This enables it to deliver high quality wound packages consistently over longer periods of time with minimum downtime and wastages. Lowered frictional and inertial losses within the machine ensure high output with surprisingly low power consumption. The assembly and disassembly of this winder is very simple reducing the chances of human error during maintenance.

EM-wind -Specifications:

Operating Speed range : 180 – 450 Metres per minute (Higher speeds available on request)

Material : PP and HDPE

Denier Range : 400 to 2000 (Higher deniers available on request)

Tape width : 1.8 mm to 4.5 mm (specially matched wind ratios for other varieties)

Traverse length : 203 mm

Maximum Package Diameter : 130 mm

Core Tube size : 35 mm I.D. 40 mm O.D. 218/220 mm length

Tension Control : via spring loaded dancer arm with graduated collar

Drive : 3 phase frequency inverter

The traverse assembly consists of a high quality hardened steel scroll cam, a cam traverse pin of hardened steel and a durable yarn guide mounted on a traversing industrial plastic sledge. The traverse assembly is housed in a distortion free and vibration resistant swinging cam housing. The cam housing exerts pressure on the wound package throughout the buildup through a pressure roll to ensure good quality of winding. The pressure roll follows the build-up of diameter of the package during winding. The pressure exerted by the roll is adjustable for individual needs. Yarn is delivered to the core via low friction surfaces, ceramic yarn guides and rotating pulleys with ceramic coated surfaces. These surfaces contribute to trouble free long service life and preserving tape quality during winding. Specially matched winding ratios are available to wind a wide variety of widths and deniers in PP and HDPE.

Electricals:

The winder motor is specially designed for higher efficiency and is controlled by a 3 phase frequency inverter. The inverter ensures constant winding tension in the wound package at all stages of operation. This ensures excellent unwinding performance of these packages in the circular looms during weaving. Winding tension is adjustable via a spring loaded dancer arm with a graduated collar. The inverter is factory programmed with a host of user friendly features like yarn break sensing, delay timers for yarn string up and synchronization with last roller of godets for smooth doffing at all speeds. It also has built-in protective features like thermal and voltage overload sensing for the motor, tripping and auto resetting of inverter to counter machine operator errors like clamping and holding of core release brake during operation of motor. Isolation transformers are provided with the winders to ensure good quality electrical supply from the mains to the winders.

Layout:

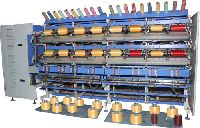

EM-wind is available in a specially designed robust frame which consists of 4 columns of winders each with 7 positions. 28 winders occupy a floor space of only 2 metres in length and 0.7 metres in depth. The height of the frame is 1.8 metres. This results in space saving while maintaining excellent ergonomics for the operator. Reduced length of winders in a tape-line helps the winder operators to control tapes more efficiently.

The energy efficiency, low maintenance and operational features make Cheese Winder Model EM-wind the ideal choice for high output tape-stretching lines. Equipped with a very high price-performance ratio this winding machine is amongst the best solutions available for the woven sacks industry today.