Listing ID #4095172

Company Information

Ask for more detail from the seller

Contact Supplier

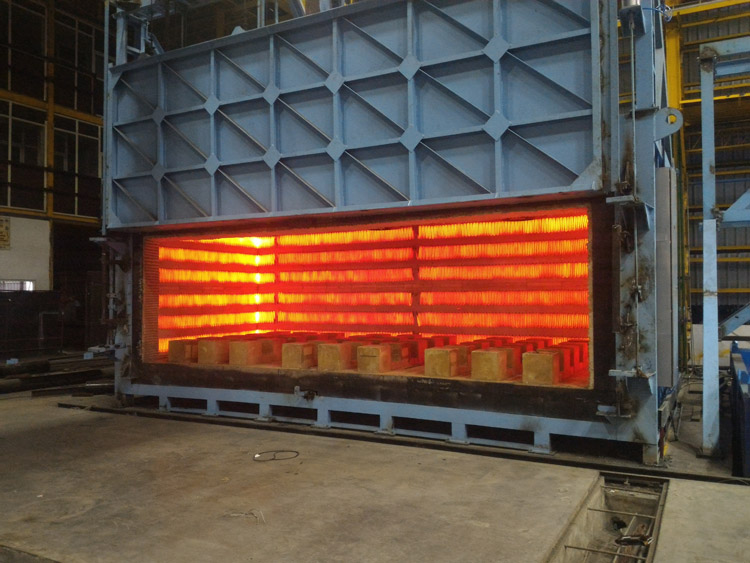

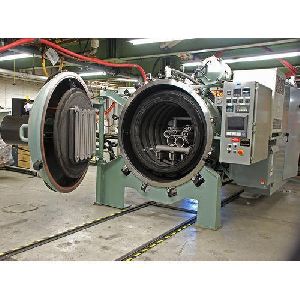

Latest, Strong, Sturdy, PLC/PC Controlled Heating Quenching Technology by Dhanaprakash MN Steel Hardening, SS Solution treatment, Forging, Quenching, Tempering & Normalising. Also available for PWHT (Post Weld Heat Treatment) (N+Q+T & Q+T)

Applications

Auto cycle control