Company Information

Ask for more detail from the seller

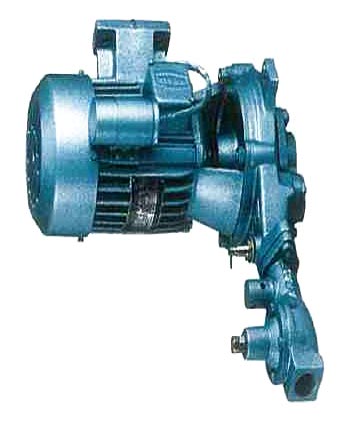

Contact SupplierCentrifugal Jet Pump Set that we supply is the product engineered to provide perfect solution for various pump set problems. The volute chamber and impellers of Centrifugal Jet Pump Set is designed to provide the best possible hydraulic efficiency and suction lift characteristics. Sealing is by means of a below mechanical seal made of carbon and ceramic is fitted over the shaft, which is ground to close tolerance. Pump sets are available in single stage, double stage and multi stages for various needs. Centrifugal Jet Pump Set is powered by a totally enclosed fan cooled (TEFC) and screen protected drip proof (SPDP), AC induction two pole motor suitable for continuous duty.

Motor stator is made of low watt loss silicon steel laminations. Dynamically balanced rotor ensures vibration and noise free operations and increases the life of the bearings and seal. The windings are of high-grade enameled copper wire and are varnish impregnated. Construction of motor frames and usage of quality materials result in high performance and low temperature rise thereby increasing the life cycle of the motor. A Thermal cutout relay (Motor protector) is incorporated in all single-phase pump sets require an adequate starter / motor protection control panel. Most of the models of our Centrifugal Jet Pump Set are specially designed to install the pump vertically above the borewell or horizontally at a little offset distance from the well according to customer's convenience.

Our Centrifugal Jet Pump Set is available in twin type and packer type versions. Packer type is suitable for 2" and 3" borewells and twin types is suitable for borewells with a diameter of 3 inch and above in twin type jet pump sets, there are two pipes, viz. Suction pipe and pressure pipe which connects the jet assembly to the pump. Pressurized water flows through the pressure pipe to the nozzle from the pump casing. Water sucked through the foot valve and the water passing through the nozzle mix together and flow through suction pipe into the pump, and for packer type jet pumps, the casing of tube well does the function of pressure pipe, ie., pressurized water through the tube well casing and enters the nozzle. Hence, one pipe eliminated.

Applications :

Salient Features :

Pumped Liquids : Clean, thin, non-aggressive, non-explosive, clear, cold, fresh water without abrasives, solid particles or fiber having the following characteristics.

| Power Range | 0.37kW to 1.1 kw (0.5 HP – 1.5 HP) |

|---|---|

| Speed | 2880 RPM |

| Versions | Single – phase 220 – 240V, 50hz, Ac supply (Permanent spilt capacitor – PSC). Three-phase 380 – 415V 50Hz, AC supply. |

| Maximum delivery head | Upto 29m |

| Maximum flow rate | Upto 3.1m3/hr |

| Degree of protection | IP 44 |

| Direction of rotation | Clockwise viewed from driving end, anticlockwise viewed from driving end (A18, A19, A40, A41 |

| Class of insulation | A/B |

| Maximum suction lift | 58 m |

| Type of duty | S1 (Continuous) |

| Nominal pumpset size (sunction x delievey x pressure) | 40x32x25, 32x25, 25x25x25& 25x20 x 25 mm |

| Maximum liquid temperature | 33 oC |

|---|---|

| Permissible amount of sand | 25 gm/m3 (max.) |

| Chloride ion density | 500 ppm (max.) |

| Allowable solids | 3000 ppm (max.) |

| Specific gravity | 1 |

| Hardness (Drinking water) | 300 |

| Viscosity | 1.75 x 108 m2/sec |

| Turbidity | 50 ppm silica scale |

| PH value | 6.5 to 8.5 |

| Part Name | Material |

|---|---|

| Rear Cover / Bracket | Cast Iron |

| Motor frame | Cast iron / Aluminium |

| Shaft | SS AISI 410 |

| Impeller | Cast iron / brass |

| Pump casing | Cast iron |

| Sealing | Mechanical seal (Carbon & ceramic) |