Listing ID #3818724

Company Information

Ask for more detail from the seller

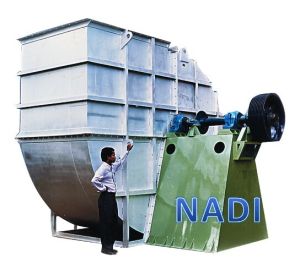

Contact Supplierentaire is best leading company of centrifugal axial jet inline fan, and best deals in centrifugal axial jet inline fan supplier. We are best leading in centrifugal axial jet inline fan manufacturer in all over delhi ncr and all over india.

Jet engine compressors provide the compression part of the jet engine thermodynamic cycle.

Centrifugal axial jet inline fan, centrifugal axial jet inline fan supplier, centrifugal axial jet inline fan manufacturer, best centrifugal axial jet inline fan in delhi, centrifugal axial jet inline fan in india I in delhi, in india, ventaire.in

There are three basic categories of jet engine compressor:

1. Axial compressor

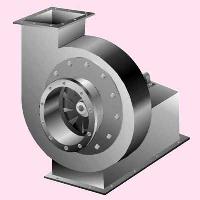

2. Centrifugal compressor

3. Mixed flow compressor

Axial compressors are used in medium to large thrust jet engines, because the alternative centrifugal units would be too heavy and too large in cross-sectional area.

At smaller sizes, the axial blading at the rear of the compressor loses its robustness and is difficult to manufacture accurately. Consequently, manufacturers tend replace the rear stages with a centrifugal unit. The compression system is then said to be axial-centrifugal.

At even smaller sizes, particularly in turboprop/turboshaft applications, the compression system is either a single centrifugal or has two centrifugal units connected in series (i.e. double-centrifugal).

In the future, mixed flow compressors may feature at the small end of the market, particularly in turbofans, where the relatively large diameter across the diffuser of a centrifugal compressor is a significant disadvantage.

At high overall pressure ratios, the compression system is usually split into two units; a Low Pressure (LP) Compressor mounted on one shaft followed by an High Pressure (HP) Compressor mounted on the HP shaft and driven by its own (HP) turbine. On civil turbofans, the first stage of the LP Compressor is often a single stage fan. If the HP Compressor pressure ratio exceeds about 4.5:1, then the unit will probably have variable geometry (i.e. variable stators) on the first few stages, to make the surge line on the compressor map more shallow, to accommodate the shallow working line.

On their large civil turbofans, Rolls-Royce split the compression system into three: a Fan, an Intermediate Pressure (IP) Compressor and an HP Compressor, each unit being driven by its own turbine unit. The RB199 military turbofan also has this arrangement.