Listing ID #4333265

Company Information

Ask for more detail from the seller

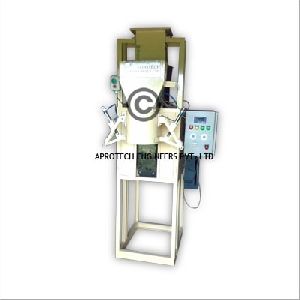

Contact SupplierThe F44 centre filler has been developed from the proven F42 centre filling machine. The centre filler machine has been continually improved and now has many new features. The drive is through an Inverter controlled geared motor with a speed control potentiometer on the operator control panel.

The storage hopper is heated either electrically or by hot water, depending on the product to be used. If electrical heaters are used, these are controlled through a simmerstat, with the temperature control on the operator control panel.

The centre filler is usually supplied as part of the complete hard candy processing line manufactured by A.M.P-Rose, but it can also be incorporated into an existing production line.

The drive unit, pump assembly and product hopper are mounted to a steel fabricated base fitted with 152 mm diameter rust-proof castors, which allows the centre filler to be easily moved when necessary. The product hopper is made from food-grade stainless steel and painting is to food finish standards. As an alternative, the centre filler can be supplied as a completely stainless steel unit.

Products

Suitable for most types of liquid and viscose paste filling materials, for example jams, creams, fondants and chocolate pastes.

Operation

A batch of prepared filling mixture is either pumped or manually loaded in to the stainless steel hopper (approx. 50 litre capacity). The heater around the hopper maintains the temperature of the mixture at the desired level.

The primary feed from the hopper is by a stainless steel auger, which ensures a smooth positive flow to the pump. The pump unit consists of a stainless steel rotor, which maintains a constant seal across the neoprene stator.

The seal is maintained throughout the pump and gives a uniform and positive displacement. This provides a constant non-pulsating flow, which eradicates the problems normally associated with a piston pump.

The rate of flow is finely controlled due to the drive mechanism. This can be regulated by the operator by adjusting the speed control knob situated on the control panel. The filling is pumped via a flexible food quality hose and PTFE coated stainless steel lance directly into the centre of the sugar mass being formed in the adjacent batch roller.