Company Information

Ask for more detail from the seller

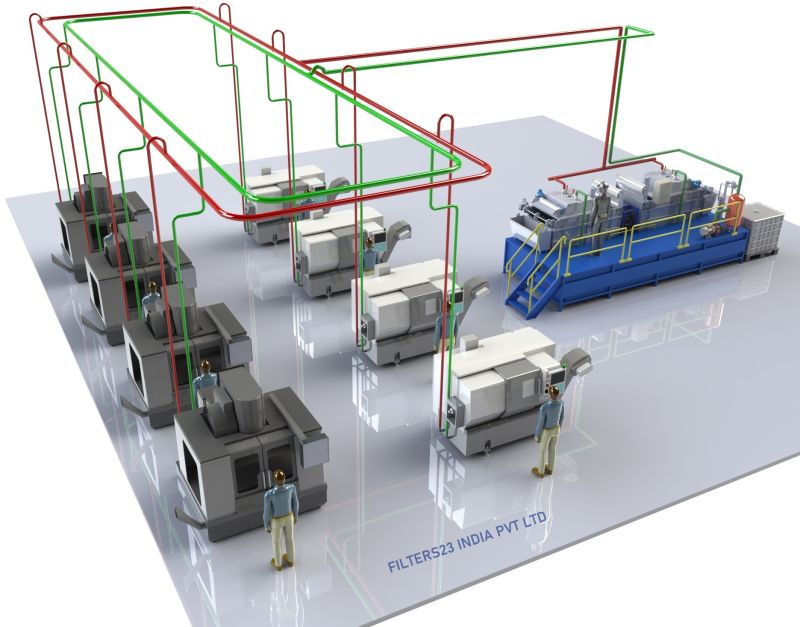

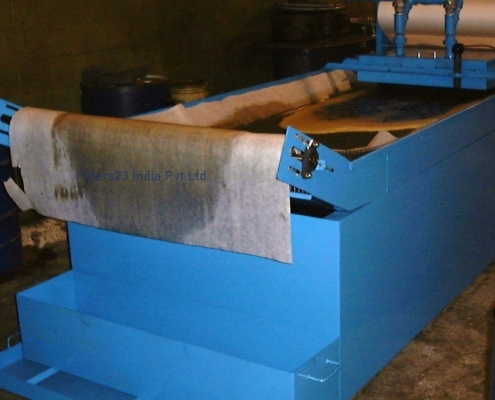

Contact SupplierCentralized filtration paper rolls often use filter paper rolls as a common filtration medium to remove impurities, contaminants, and particulate matter from fluids. These systems are commonly employed in various applications, including industrial processes, municipal water treatment, and other large-scale filtration needs. Here's how centralized filtration systems typically use filter paper rolls: 1. Filtration Media Selection: In a centralized filtration system, the choice of filter paper roll is critical. Filter paper rolls are selected based on the specific requirements of the application, including the type of fluid being filtered, the size and nature of contaminants, and the desired filtration efficiency. The filter paper roll should have an appropriate filtration rating measured in microns to effectively capture the desired particle sizes. 2. Fluid Circulation: The fluid to be filtered is circulated through the filtration system. In the case of water treatment plants, for example, raw water enters the system and passes through the filter paper roll to remove impurities and contaminants. In industrial processes, the fluid may be a coolant, hydraulic fluid, or another liquid requiring filtration. Filtration Rating: A micron (µm) is a unit of measurement equal to one-thousandth of a millimeter (0.001 mm). Micron filter paper is rated based on the size of particles it can retain. For example, a 10-micron filter paper can capture particles that are 10 micrometers or larger in size. Filter Material: Micron filter paper is typically made from cellulose or synthetic fibers. The choice of material depends on factors like compatibility with the fluid being filtered, the required filtration efficiency, and the operating conditions (temperature, chemical resistance). Filtration Process: When a fluid passes through micron filter paper, the filter media traps and retains particles that are larger than the rated micron size. Smaller particles that are below the specified micron rating will pass through the filter. Common Applications: Water Filtration: Micron filter paper is used in various water treatment applications to remove suspended solids, sediments, and particulate matter from drinking water, wastewater, and industrial process water. Industrial Filtration: In industrial processes, micron filter paper is used to filter liquids such as hydraulic fluids, lubricants, cutting fluids, and coolant fluids. It helps maintain the quality of these fluids by removing contaminants that could damage equipment or reduce performance. Pharmaceuticals: Micron filter paper is used in pharmaceutical manufacturing for sterile filtration, ensuring that liquids and solutions are free from particulate matter and microorganisms. Food and Beverage: It is used in the food and beverage industry to clarify liquids such as fruit juices, edible oils, and , ensuring they meet quality standards. Automotive: Micron filter paper is used in automotive filters, including oil filters and fuel filters, to remove particles and contaminants from engine fluids. Filter Selection: Choosing the right micron rating for filter paper depends on the specific application and the desired level of filtration. Finer micron ratings are used when high purity is required, while larger micron ratings are suitable for removing larger particles. Maintenance: Regular maintenance is necessary to ensure that the filter paper remains effective. As the filter accumulates contaminants, it may need to be replaced or cleaned, depending on the filtration system and the application. Filter Configuration: Micron filter paper can be found in various forms, including filter rolls, filter sheets, and filter cartridges, to accommodate different filtration equipment and systems. Micron filter paper is a versatile filtration medium that plays a critical role in ensuring the quality and purity of fluids in various industries and applications.