Listing ID #7144679

Company Information

Ask for more detail from the seller

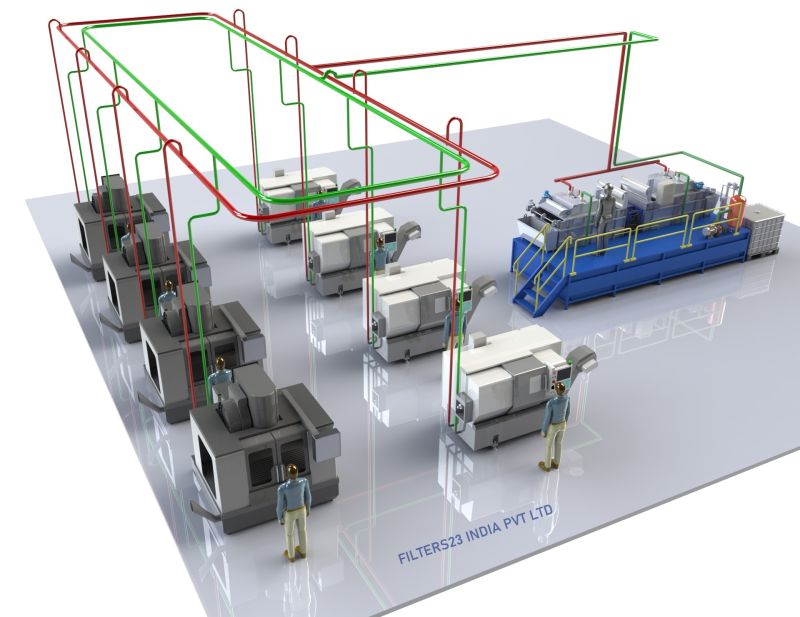

Contact SupplierCentralized Coolant Filtration Systems

Filters 23 india centralized coolant filtration system involves several stages to maintain the quality and effectiveness of the coolant or cutting fluid used in industrial machining and metalworking processes. Below is a step-by-step overview of how these systems typically operate:

Coolant Collection: The process begins with the collection of the coolant or cutting fluid used in machining operations. This fluid is typically collected in a central reservoir or sump, which serves as the primary storage location.

Circulation: Pumps are employed to circulate the coolant from the reservoir through the filtration system and back into the machining process. This circulation ensures a continuous flow of coolant to the machining area, where it provides cooling and lubrication to cutting tools and workpieces.

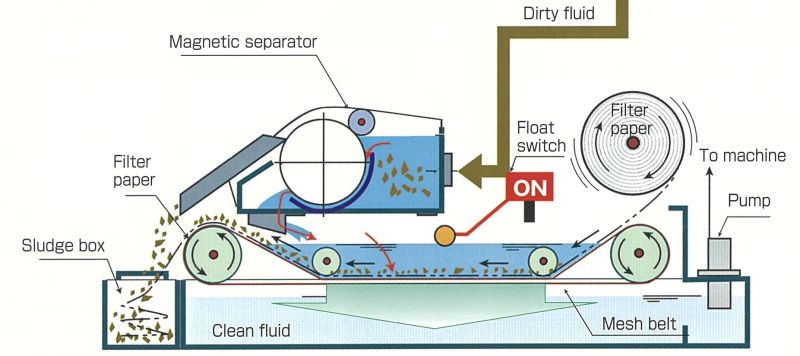

Filtration: The coolant is directed through various filtration units, which are designed to remove contaminants and particulate matter. Common types of filters used in centralized coolant filtration systems include cartridge filters, bag filters, magnetic separators, and sometimes centrifuges. These filters capture solid particles, metal chips, and other impurities, preventing them from circulating in the machining process.

Cleaning and Maintenance: Over time, the filters become clogged with captured contaminants. To maintain the filtration efficiency, the system employs a cleaning mechanism. This can be done in one of two ways:

Manual Cleaning: Operators manually remove and clean the filters as needed, typically on a regular maintenance schedule.

Automatic Cleaning: Many systems are equipped with automated cleaning mechanisms that use methods like backwashing (reversing the flow through the filter), mechanical scraping, or air purging to dislodge and remove accumulated contaminants.

Monitoring and Control: Centralized coolant filtration systems often include sensors and monitoring devices to assess various parameters:

Coolant Quality: Sensors measure the quality of the coolant by detecting levels of contaminants, oil, and other factors.

Flow Rates: Flow sensors monitor the flow rate of coolant to ensure it meets the machining requirements.

Filter Condition: Sensors track the condition of filters and trigger cleaning or replacement when necessary.

Coolant Concentration: Some systems monitor the concentration of the coolant mixture and adjust it as needed by adding coolant concentrate and water.

Waste Separation: Separated contaminants, such as metal swarf and solid debris, are collected and separated from the coolant. This may involve settling tanks, centrifuges, or other separation equipment.

Coolant Reuse: After filtration and cleaning, the coolant is returned to the central reservoir. This ensures that the coolant remains in good condition for reuse in machining processes, reducing the need for frequent coolant replacements.

Disposal of Waste: Collected contaminants and waste materials are typically disposed of in an environmentally responsible manner, following local regulations.

The continuous operation of a centralized coolant filtration system helps maintain consistent coolant quality, prolongs the life of cutting tools, reduces machine downtime, and minimizes waste generation. The specific design and components of these systems may vary depending on the industry, application, and the type of contaminants present in the machining processes. Proper maintenance and monitoring of the system are essential to ensure optimal performance and extend the life of the coolant.

Our company, Filters 23 India PVT LTD, located in Surendranagar (Gujarat), is a trusted organization that manufactures products like centrifugal filtration systems, compact band filters, coolant magnetic separators, coolant filter paper, etc. We, at Filters 23 India PVT LTD, are highly determined to our work and devoted to delivering the best value to our clients. By maintaining quality standards of the offered products and offering excellent customer service, we want to secure a distinct position in this field. We aim to gain the trust of numerous clients across domestic and overseas markets.

Fortunately, we are supported by a team of efficient & dynamic people who are very zealous and tackle all the troubles that come on their way in their daily activities in the company. They ensure the availability of adequate stock of every item all the time to cater to the rising market demands. Our professionals ensure that the right kind of raw material is procured from the vendors and used properly to manufacture the product range.

We have a state-of-the-art infrastructural base where all the processes including product development, quality testing, storing, packing, and distribution processes are carried out with ease. Our facilities are equipped with the latest technology, machines, and tools that facilitate our production rate. In addition to this, all new and innovative ideas & techniques are used for our whole business process.

Under the leadership of Mr. Dhruv, we are working to attain our business targets efficiently and carve a niche for ourselves in the market.