Company Information

Ask for more detail from the seller

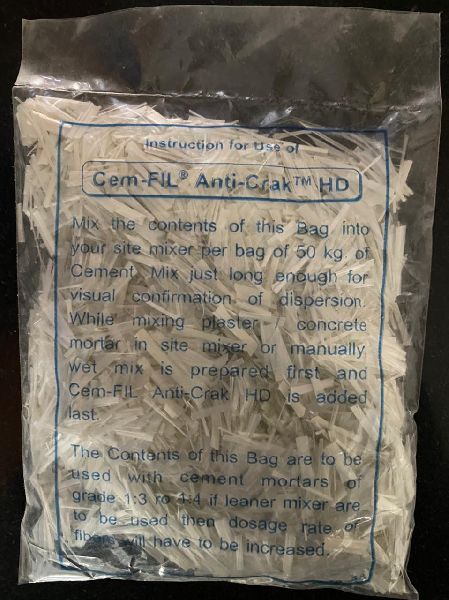

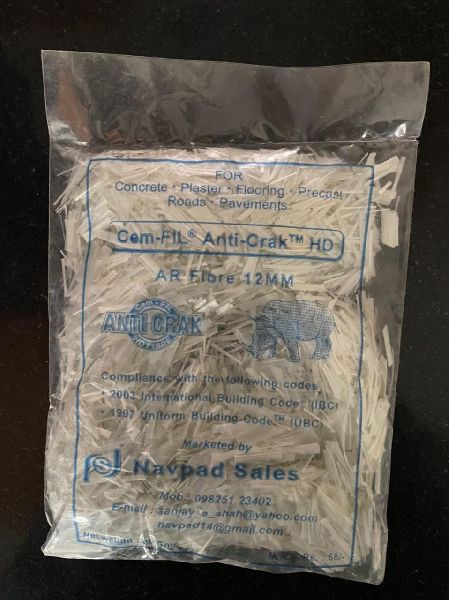

Contact SupplierAnti-Crack HD (High Dispersion) is an engineered AR-glass chopped strand designed for mixing in concrete and all hydraulic mortars. Anti-Crack HD fibers are typically used at low addition level to prevent cracking & improve the performance of concrete, flooring, renders or other special mortar mixes.They incorporate easily into mixes creating a multidimensional homogeneous network of reinforcement in the matrix.Anti-Crack?? HD fibres can be added at the central mixing plant to the wet concrete mix; or directly into the ready-mix truck PRODUCT DESCRIPTION ADVANTAGES AND BENEFITS FEATURES (nominal values)PRODUCT APPLICATIONAnti-Crak HD (High Dispersion) is an engineered AR-glass chopped strand designed for mixing in concrete and all hydraulic mortars.Anti-Crak HD fibers are typically used at low addition level to prevent cracking & improve the performance of concrete, flooring, renders or other special mortar mixes.They incorporate easily into mixes creating a multidimensional homogeneous network of reinforcement in the matrix.Anti-Crak?? HD fibres can be added at the central mixing plant to the wet concrete mix; or directly into the ready-mix truck.-Anti-Crak HD fibres do not protrude through the surface and require no additional finishing procedures. -The reinforcement is incorporated in the concrete mass and is invisible on the finished surface.-High dispersion (220 million filaments per kg, 100 million per lb)-Excellent workability- Invisible on the finished surface- Does not corrode -Control and prevention of cracking in fresh concrete- Overall enhancement of durability and mechanical properties of concrete- Effective at very low dosage- Homogeneous mix- Safe and easy to handle- Fiber length: 12 mm - Filament diameter: 14m, (0.000546 in)- Loss on Ignition: 0.55% (ISO 1980: 1980)- Moisture: 0.3% max (ISO 3344: 1977) Material: Alkali Resistant Glass* Specific Gravity: 2.68 g/cm3 Softening point: 860??C - 1580??F-Electrical Conductivity: Very low-Chemical Resistance: Very highModulus of elasticity: 72GPa - 10 x 106 psi-Tensile Strength: 1,700 MPa - 250 x 103 psi* Anti-Crak HD fibres are part of Cem-FIL product rangeQUALITY STANDARDS CERTIFICATIONFibres can be introduced directly in the ready mix plant or directly in the concrete truck.Recommended dosage is 600 g/m3 (1 lb/cum) of concrete to control plastic shrinkage crackingAnti-Crak HD fibres are packed in individual paper bags (water dispersible) or in plastic bags.Anti-Crak HD fibres should be stored away from heat and moisture, and in their original packaging.The best conditions are:- Temperature: 15C - 35C.- Humidity: 35% - 65%.Hear I provide you a Price for your Demanded product quality.Anti-Crak 25. KG BAGS