Listing ID #3859927

Company Information

Ask for more detail from the seller

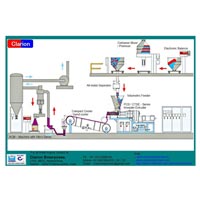

Contact SupplierElectrocoating, which is also referred to as electro deposition, electrophoretic deposition, CED Coating, CED Painting or electropainting, is an organic finishing process that uniformly applies thin-film primers and one-coat finishes to metallic substrates. Electrocoating resembles electroplating in that it utilizes an electrical current to deposit a coating onto substrates. However, electrocoating deposits water born paint onto substrates rather than metal ions.

The overall process consists of four main process steps: Pre-treating, Electrocoating, Rinsing, and Baking. The electrocoating process may be anodic or cathodic, depending on the charge applied the substrate. Although the processes are virtually the same, properties of the resultant coating are dissimilar. Anodic systems, which were the first to be used for electrocoating, apply paint to positively charged substrates. The negatively charged pigment and resin particles deposit onto the substrate (anode). One disadvantage of this process is that substrate metals dissolve and become incorporated into the coating, which affects surface properties. Cathodic electrocoating deposits paint onto negatively charged substrates and offers several advantages over anodic electrocoating. For example, metal dissolution of the substrate does not occur, cathodic electrocoating has the ability to deposit over contaminants, corrosion resistance is improved, and a better color consistency occurs over welded areas.