Listing ID #3586668

Company Information

Ask for more detail from the seller

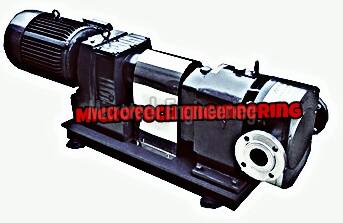

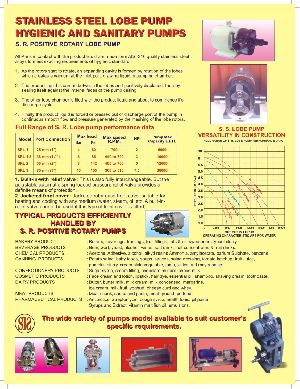

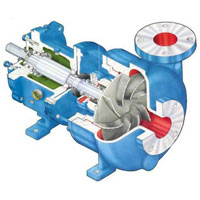

Contact SupplierMicrotech engineering Lobe pumps are used in a variety of industries including, pulp and paper, chemical, food, beverage, Pharmaceutical, and biotechnology. They are popular in these Diverse industries because they offer superb sanitary qualities, high efficiency, reliability, corrosion resistance, and good clean-in-place and sterilize-in-place (CIP/SIP) characteristics. These pumps offer a variety of lobe options including single, biwing, tri-lobe (shown), and multi-lobe.Rotary lobe pumps are Non-contacting and have large pumping chambers, allowing them to handle solids such as cherries or olives without damage. They are also used to handle slurries, pastes, and a wide variety of other liquids. If wetted, they offer self- priming performance. A gentle pumping action minimizes product degradation. They also offer reversible flows and can operate dry for long periods of time. Flow is relatively independent of changes in process pressure, so output is constant and continuous.

How Lobe Pumps Work Liquid flows into the cavity and is trapped by the lobes as they rotate :

Advantages

Disadvantages

Application : Alcohol - Apple pure – Apricots - Baby food – Batter – Beans – Beetroot - Biscuit Cream – Blackcurrants – Brine –Broth -Butter fat Caramel - Castor Oil - Cat food - Cheese curd - Cheese whey – Cherries - Chicken paste - Chili con – Carne –Chocolate – Chutney – Cockles - Coconut oil - Cod oil – Coffee –liquor – Cordials -Corn oil - Corn syrup – Cottage – cheese - Cotton seed – oil –Cranberry --- juice - Cream – Cream cheese – Custard - Dog food – Dough – Eggs – whole - Egg yolk – Essences – Evaporated –milk -Fish –- Iodine - ointment etc