Listing ID #4095202

Company Information

Ask for more detail from the seller

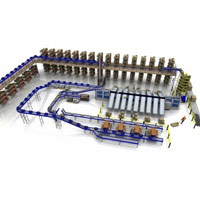

Contact SupplierMECHANICAL SAND RECLAMATION SYSTEM

After knockouts Sand lumps are fed to a lump reducer “Vibraclaim” where due to vibratory gyratory motion lumps abraded with each other to release the original sand grain.

The abraded sand grains and fines are then fed to classifier, where mixture is fluidized to remove fines.

If sand lumps are hot water cooled tubes are used to cool the sand.

Dust collection system collects all fines which are disposed off.

Above system is used for mechanical reclamation system. for small foundries.

THERMAL SAND RECLAMATION

When sand to metal ratio is high and total quantity of sand replenishment goes high thermal sand reclamation is used to eliminate the waste sand and stop buying new sand thus double environment impact.

The thermal reclamation starts with mechanical reclamation. The mechanically reclaimed sand is pass through calciner to burn off the chemicals to get reclaimed sand which is better than new sand.

This technology is suitable for: