Company Information

Ask for more detail from the seller

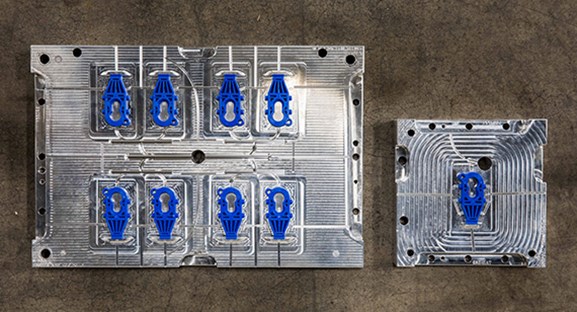

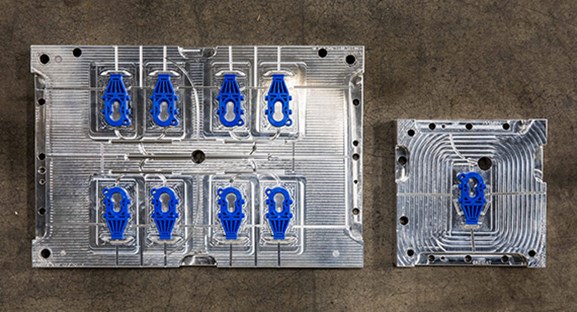

Contact SupplierWe have two injection molding service options—prototyping and on-demand manufacturing—and each offers its own benefits depending on your project needs. If part quantities are higher, an affordable piece-part price is important, and quick-turn production throughout your product life cycle is critical, our on-demand manufacturing option is ideal.

Why Use an On-demand Manufacturing Tool?

Low-volume Runs

Bridge Tooling

Optimizing Supply Chain

Reduce Production Costs