Listing ID #6114107

Company Information

Ask for more detail from the seller

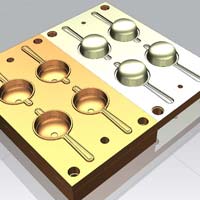

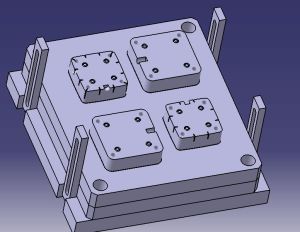

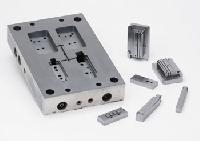

Contact SupplierOur rapid overmolding and insert molding processes produce custom prototypes and on-demand production parts in as fast as 15 days. We use aluminum molds that offer cost-efficient tooling, producing parts from a range of thermoplastic and liquid silicone rubber materials.

Common Applications

What is Overmolding?

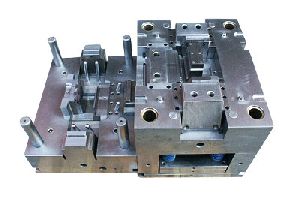

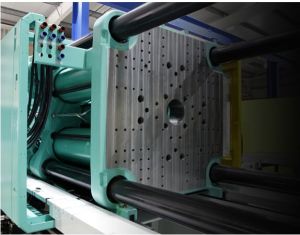

With overmolding, the production of the substrate parts is a standard injection molding process involving an aluminum mold with no heating or cooling lines running through it. Cycle times are a bit longer, which allows our molders to monitor fill pressure, cosmetic concerns, and the basic quality of the parts. When the total run of substrate parts are molded, overmold tooling is then assembled to the press. The substrate parts are placed by hand into mold where each part is overmolded with either a thermoplastic or liquid silicone rubber material.

What is Insert Molding?

Insert molding is a similar process but instead uses a preformed part—often metal—that is loaded into a mold where it is then overmolded with a thermoplastic resin to create a final component. When the run is complete, parts are boxed and shipped shortly thereafter.