Listing ID #1624164

Company Information

Ask for more detail from the seller

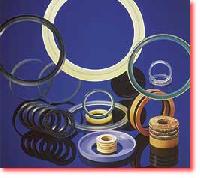

Contact SupplierWe are the trustworthy Manufacturer and Supplier of the best quality Cartridge Seal (FSI C62). Cartridge Seals are self-contained units consisting of a shaft sleeve, seal, and gland plate. The unit is fitted onto the pump shaft as a built assembly, and no further fitting is required. Cartridge Seals are an attempt to over-come the fitting problems of conventional seals. Cartridge Seals are supplied in single and double form, and the gland plate is often fitted with various tappings to provide for flushing, cooling water injection, and disaster control. The cartridge can overcome several limitations of the standard pump gland. Tangential tappings for introducing fluids into the gland cause fewer disturbances to the seal face than the radial tappings often found on pump units. Look again at the tapping provided for flush water to the packed gland, a tangential tapping would provide a less turbulent water source. For a packing gland this may not be important but to a mechanical seal it can be another adverse condition with which to cope. The setting position of the seal is set by the cartridge design, but the seal unit should not be screwed to the shaft until the gland plate is secured to the pump and any adjustments made to the shaft position. Once this has been completed the set screws can be tightened and the spacers removed. The design works to eliminate many of the common causes of seal failure on installation and because the seal is presented on its own shaft sleeve any damage that might be caused by a conventional seal to the pump unit is also eliminated.