Listing ID #3879508

Company Information

Ask for more detail from the seller

Contact SupplierFlair Cartridge & Bag Filter Offers Affordable and Excellent Filtration Solutions

Flair Strainers & Filters is a leading engineering company in India manufacturing a range of high quality products for different industrial applications. We manufacture Cartridge & Bag Filters that give efficient filtration solutions for many filtering applications according to tailor-made requirement of customers. We offer cost-effective and user-friendly alternative for different liquid filtration applications with benefits of favorable operating cost.

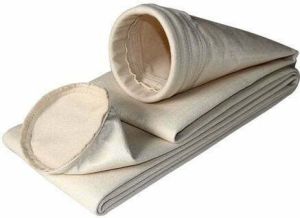

Flair cartridge filters are manufactured using disposable filter cartridge of Cellulose, Fiberglass, Ceramic, Polypropylene Nylon, Bleached cotton, and Sinter metal which gives filtration down to 0.45 microns. Filter bags are also available in various materials. Present days, Pleated type filter elements made of fine wire mesh are very popular. Pleated Element are cleaned with suitable means and can be reused. Wire mesh pleated cartridges are also reusable after cleaning.

Cartridge filters are suitable for fine filtration and generally used after some kind of coarse filter in the system. These Filters are suitable for many liquid fluids or gases and are available in simplex or duplex type construction. Cartridge filters are useful in the systems having contaminations below 100 ppm or contamination levels below 0.01% in weight.

Bag filters are used for industrial application for removing dust. The particle separation process takes place on the surface from outside to inside or inside to outside of the filter depends on the application. Normally, the Particles are captured on the bag filter’s internal surface. Some Bag filters which are used in gaseous applications to remove dust can be cleaned and reused.

All about Cartridge & Bag Filter