Company Information

Ask for more detail from the seller

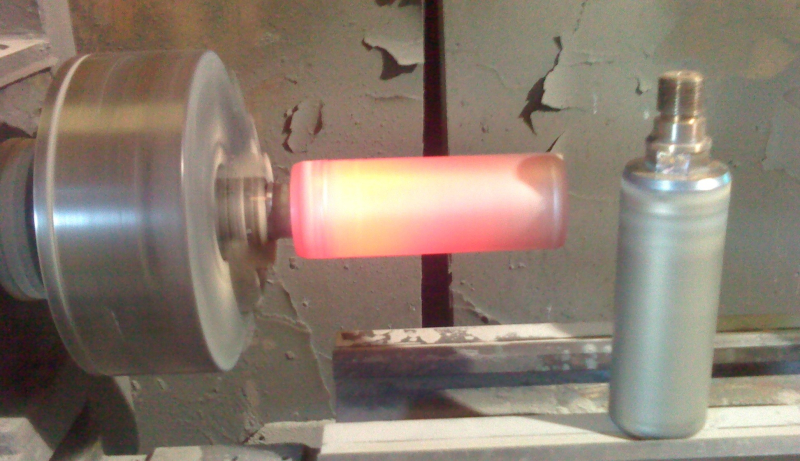

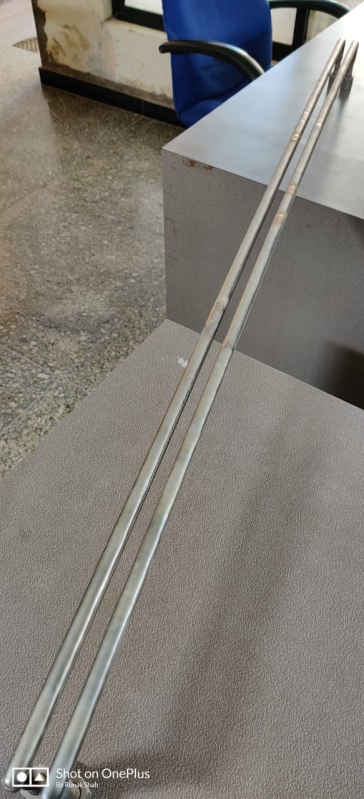

Contact SupplierCarbide coatings are typically used for wear resistance to abrasion, erosion, galling, and fretting. Most “carbide” coatings are applied by HVOF to achieve the densest and most well-bonded coatings available by thermal spray. For Higher Thickness, Weld Overlay of TIG, MIG or PTA or LASER process severe process application.

There are several different chemistries of “carbide” coatings including:

Types of Carbide Coatings

Tungsten Carbide/Cobalt

Tungsten Carbide/Nickel-Chrome

Chrome Carbide/Nickel-Chrome

Tungsten Carbide/Cobalt/Chromium

Carbide Coatings Resist:

Fretting

Sliding Wear

Erosion

Abrasion

Galling

Some Impact

Benefits of Carbide Coatings

High Hardness, Durability And Toughness

Abrasion And Erosion Resistance

Some Corrosion Resistance

Fretting Resistance

Anti-Galling Properties

Long Lasting Traction Surface application.