Listing ID #4333298

Company Information

Ask for more detail from the seller

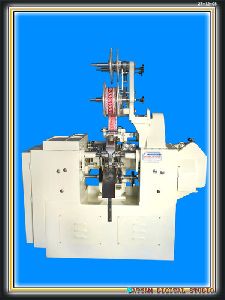

Contact SupplierThe CF4 candy former is at the heart of the candy processing line and has therefore been designed with strength and durability as its main assets. A substantial cast iron frame supports the drive, candy feed rollers, die head and the integral conveyor/spreader discharge.

The candy former has a number of features, which make it an ideal choice for candy manufacturers.

Output

A maximum of 100 die revolutions per minute can be achieved. For asweet diameter of 20mm weighing 5 grams this equates to 1320kgs/hour.

Candy Former Dies

As well as supplying ‘Uniplast’ type dies for the CF4 machine, we can also provide dies suitable for other machines, such as Super Robust, Super/ Baby Rostoplast, ‘Strada’ type chain dies etc. We even supply dies for lollipop forming machines. Die lifting and die washing machines are also available.

Technical Data

OUTPUT