Listing ID #3396735

Company Information

Ask for more detail from the seller

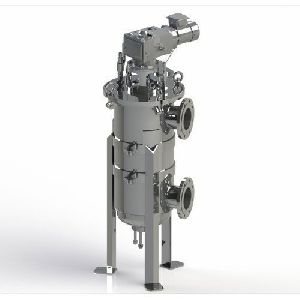

Contact Supplierschematic industries candle filters comprise of a group of columnar filter elements sealed within a pressure vessel to produce a cake with dry solids contents as high as 80% and filtrate of extremely high clarity.

our candle filters are customisable and provide for thin-cake pressure filtration, cake washing, drying, re-slurry and automatic discharge as well as heel filtration. They are typically installed for clarification and recovery applications from liquids with low solids content from 5% to less than 1% solids and even down to trace amounts.

the schematic candle filters are a safer solution than traditional leaf filters as in a leaf filter the carbon has to be removed manually with each operation. As carbon is a pyro-hazardous material it poses a significant risk to operators involved in filtering and cleaning equipment. Our multi-tube carbon filter design provides automatic discharge, whereby the carbon is directly discharged into a container without any manual human contact.

as filtrate is pumped into filter, mother liquor is sent to ml tank and solids are collected on filter candle(s). By reverse flush method, wet cake is discharged and collected into a container positioned below the filter. As filtration is completely contained, candle filters are ideal for processing solvents, concentrated acids and other toxic products.

design features