Company Information

Ask for more detail from the seller

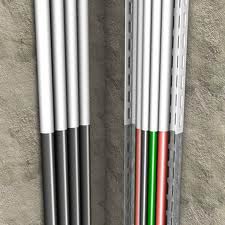

Contact SupplierThe Cable Coatings that we offer are water-based and solved-free coatings comprising thermoplastic resins, flame redundant, inorganic fiber, filler and pigment. Cable Coatings are an ablative product that prevents flame propagation along the vertical and horizontal tray. Cable Coatings last for lifetime and are used for de-rating of cable and work perfect for most outdoor applications. The wide range of Cable Coatings we offer is available at an affordable rate.

Application Areas :

The use of Cablemastic SFR-999 is reommended based on international specifications and code of practices followed worldwide on the following areas.

Cables under control panels.

Near cable joints and around cable crossing app. 1.5 meter on both sides of joints.l

Cables affected by coal dust depositions/oil/lubricant spillage.

Cables near battery room & high temperature areas.

System | Single pack, ready to use |

|---|---|

Colour | Off white |

Odour | Odourless |

Surface finesh | Textured matt |

Density | 1200+50gm/cc |

Solids | 67+2% approx |

PH Value : 7-8 | |

Curing Time | Touch dry – 4-6 hours hard dry – 72 hours |

Water resistance | (400.C, 7 Days) no charges were observed |

Smoke density rating | Less than 35% as per Astmd 2843 |

Fire Resistance | For 20 minutes |

Flammability | For 6 hrs. |

Coverage | 2.8 kgs./M2 for single an d3.5 kgs/M2 for bunched cables to achieve 1.5 to 2 mm nominal dry coating thickness. |

Shelf life | 18 months at room temperatures |

Packing | 20 kgs. M.S. Drums. |