Listing ID #4150690

Company Information

Ask for more detail from the seller

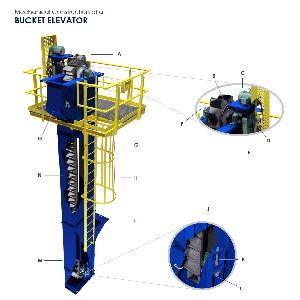

Contact SupplierBelted bucket elevator is very ideal for vertical conveying of bulk materials or products, which have particle size up to 50 mm. For procedural reasons, the elevation of products, either in silo plants or in processing plants, is compulsory in almost all cases. For this purpose, buckets, which are fixed to a belt, convey the material from the inlet at the elevator foot to the elevator head, where the buckets are emptied when the belt is redirected. The Belt and Bucket elevator MGEL is designed for conveying up to 200 tons per hour. Floury as well as fine-grained and coarse-grained materials can be elevated up to a height of 60 meters.

The whole body is fabricated from steel sheet. Because of international safety regulations, inspection and installation covers should only be opened by suitable tools. The driven system is designed to move only in one direction. Reverse movementisn't permitted. For special applications, mostly worn surfaces are supported (covered) with replaceable plates.

The working principle of Aspirator Separator is very simple and intuitive. The vibrating process is maintained by means of vibro-motors, which are placed in the machine keeping into account the centre of gravity of the machine. The grain feeding chamber and body which are mounted on the rubber shock absorbers vibrates together and propels the product into mid-section of the Aspirator Separator inlet. The grain is spread uniformly on the entire surface of the mesh by means of an adjustable regulating gate. Mukul Enterprises recommends another adjustable regulating mesh to the inlet of the conveyer for better flow. When the grain passes through from the first mesh to the second one, larger size impurities or foreign particles are filtered out by the first mesh and directed to coarse flow discharge line. The remaining smaller size impurities or foreign particles which pass through the second mesh are transferred to fine flow discharge line. Then, the cleaned product is transported to an air canal.

FEATURES & ADVANTAGES OF BUCKET ELEVATOR