Company Information

Ask for more detail from the seller

Contact SupplierJFE Steel Corporation began production and sales of abrasion-resistant steel plates in 1955, before any other company. Since that time, JFE’s abrasion-resistant steel plates EVERHARD series have been widely used in key components of construction, mining, and agricultural machinery, as well as other critical applications.

JFE Steel has succeeded in developing super abrasion-resistant steel plate EVERHARD-SP with higher abrasion-resistance than that of the Brinell hardness 500 grade. In addition, JFE Steel has developed EVERHARD-C400LE, EVERHARD-C450LE and EVERHARD-C500LE, which are produced by the leading-edge manufacturing process and guarantees low temperature toughness at −40°C (−40°F). All these products have earned an outstandingreputation with customers. This catalog introduces JFE Steel’s line-up of abrasion-resistant steel plates EVERHARD™. We appreciate your long time patronage, and we look forward to continuing to serve you in the future.

Special Features of EVERHARD

A wide variety of available grades

EVERHARD is available in 5 grades of the Standard Series and 3 grades of the High Toughness Series, which guarantees low temperature toughness of −40°C (−40°F) and also considers internal hardness. With the addition of the super abrasion-resistant grade EVERHARD-SP to these two series, the EVERHARD product line includes a total of 9 grades.

The target value (average value) of Brinell surface hardness is used in the numerical figures in the grade names so that customers can easily understand the properties of each grade. By specifying narrow ranges of Brinell hardness, consideration is given to reducing variations in formability in customers’ manufacturing processes.

Standard Series

In the Standard Series, priority is placed on the hardness of the steel with minimum addition of alloying elements to the chemical composition. The lineup now includes two new products; EVERHARD-C340, which focuses on formability in heavy-gauge products with thicknesses exceeding 100 mm, and EVERHARD-C550, which is designed especially for abrasion resistance in simpleshaped parts such as liners.

High Toughness Series

By applying a leading-edge manufacturing process, JFE Steel succeeded in developing an abrasion-resistant steel that guarantees low temperature toughness at −40°C (−40°F) in the product line up to Brinell 500 grade. These are the optimum products for applications where higher toughness or internal hardness is required, particularly for use in cold environment or in the cases with heavy impacts, etc. These materials can be used with confidence, as they also provide high weld cracking resistance performance.

Super Abrasion-Resistant Steel Plates (EVERHARD-SP)

Longer life of abrasion-resistant steel plates is constantly demanded by customers from the viewpoint of reducing running costs. However, it had been difficult to manufacture steel materials with abrasion resistance exceeding Brinell hardness 500 grade by conventional technologies due to problems with weldability and formability. EVERHARDSP, developed by JFE Steel, provides higher abrasion resistance than that of the Brinell hardness 500 grade without sacrificing weldability and formability.

Superb quality

JFE’s abrasion-resistant steel plates are produced at the company’s state-of-the-art steel works with the most advanced heat treatment technologies, based on long years of experience, under high level quality control. EVERHARD certainly provides not only excellent abrasion resistance, but also outstanding quality of weldability and formability.

Abrasive plate

We would like to take an opportunity to introduce our self as a Service Centre for Steel Plates, where we have joined hands with M/s Metal One Corporation, Japan as a channel partner, to locally stock and supply specialty steel plates like Abrasion Resistant steel plates, High Strength Steel Plates and Boiler/Pressure vessel grade steelplates. We are also a recognized stock and supply Channel to M/s JFE Steel Corporation, Japan.

We would like to introduce JFE’s Everhard brand Abrasion/Wear Resistant Plate. We are importing these plates from Japan and from any other overseas suppliers. We can offer you above imported materials, by locally Stock and Sales basis for small volume up to 100MT, and for bigger volume, we would introduce Metal One Corporation for direct import. We can also cut, bend and roll these plates as per the size / profiles (drawings) given by you at our well-equipped facility.

Everhard Brand is quite popular with various OEM across the world and is regularly used at following Customers like Komatsu India, Kobelco Construction Equipments, Hitachi Construction, JCB, Escorts and others.

Available Grades :

EVERHARD is manufactured for non-structural application in which chemical composition of crude steel, Brinell hardness at the plate surface and toughness are specified and guaranteed. Tensile strength and elongation which are required for structural application are not specified and guaranteed. In case of any request for the tensile strength and/or elongation as reference, please refer to JFE Steel Technical Bulletins.

Chemical composition

| Type | Brand name | Available thickness (mm) | Chemical composition (%)* | |||||||||||

| Heat treatment | C | Si | Mn | P | S | Cr | Mo | V | Ti | B | Ceq** | |||

| Standard series | EVERHARD-C340 | 38 – 160 | treatment | 0.20 Max. | 0.55 Max. | 1.60 Max. | 0.030 Max | 0.030 Max | 1.50 Max. | 0.50 Max. | 0.10 Max. | 0.020 Max. | 0.004 Max. | - |

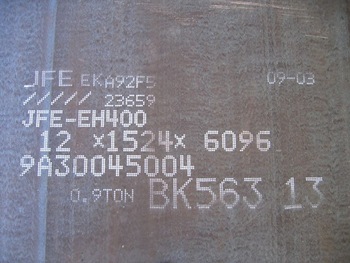

| EVERHARD-C400 | 6(5) – 50.8 | Controlled heat Treatment | 0.20 Max. | 0.40 Max. | - | - | ||||||||

| 50.9 – 101.6 | 1.20 Max. | 0.50 Max. | ||||||||||||

| EVERHARD-C450 | 6(5) – 50.8 | 0.25 Max. | 0.80 Max. | - | - | |||||||||

| 50.9 – 101.6 | 1.50 Max. | 0.50 Max. | ||||||||||||

| EVERHARD-C500 | 6(5) – 50.8 | 0.30 Max. | 0.80 Max. | - | - | |||||||||

| 50.9 – 101.6 | 1.50 Max. | 0.50 Max. | ||||||||||||

| EVERHARD-C550 | 6 – 32 | 0.35 Max | 0.80 Max. | - | - | |||||||||

| EVERHARD-C400LE | 6(5) – 19 | Controlled heat Treatment | 0.17 Max. | 0.55 Max. | 1.60 Max. | 0.020 Max. | 0.010 Max. | 0.40 Max. | 0.35 Max. | - | 0.020 Max. | 0.004 Max. | 0.40 Max. | |

| 19.1 – 32 | 0.40 Max. | 0.35 Max. | 0.43 Max. | |||||||||||

| High Toughness series | 32.1 – 60 | 1.20 Max. | 0.50 Max. | 0.58 Max. | ||||||||||

| EVERHARD-C450LE | 6(5) – 19 | 0.23 Max. | 0.80 Max. | 0.35 Max. | - | 0.50 Max. | ||||||||

| 19.1 – 32 | 0.80 max. | 0.35 Max. | 0.53 Max. | |||||||||||

| 32.1 – 50.8 | 1.20 Max. | 0.50 Max. | 0.65 Max. | |||||||||||

| EVERHARD-C500LE | 6(5) – 19 | 0.29 Max. | 0.80 Max. | 0.35 Max. | - | 0.55 Max. | ||||||||

| 19.1 – 32 | 0.80 Max. | 0.58 Max. | ||||||||||||

| 32.1 – 50.8 | 1.20 Max. | 0.50 Max. | 0.70 Max. | |||||||||||

| Super grade | EVERHARD-SP | 6 – 65 | Controlled heat Treatment | 0.35 Max. | 0.55 Max. | 1.60 Max. | 0.030 Max. | 0.030 Max. | 0.50 – 1.50 | Contains other alloying elements | ||||

( ) Please inquire for thicknesses shown in parentheses.

* Elements not shown in the table may be added when necessary. The chemical compositions shown here are based on molten steel analysis.

** Carbon equivalent Ceq = C+Mn/6+(Cu+Ni)/15+(Cr+Mo+V)/5

| Type | Brand name | Thickness (mm) | Brinell hardness [guaranteed] (29.42 kN) Average of 5 points | Charpy impact properties (2mmV) | Ceq (%)* [guaranteed] | |

| Test temperature (C°) | Charpy absorbed energy (J) [guaranteed] | |||||

| Standard series | EVERHARD-C340 | 38 – 160 | 340±30 | - | - | - |

| EVERHARD-C400 | 6(5) – 101.6 | 400±30 | ||||

| EVERHARD-C450 | 6(5) – 101.6 | 450±25 | ||||

| EVERHARD-C500 | 6(5) – 101.6 | 500±40 | ||||

| EVERHARD-C550 | 6 – 32 | 550±40 | ||||

| High Toughness series | EVERHARD-C400LE | 6(5) – 11.9 | 400±30 | - | - | ≤0.40 (5≤t≤19) ≤0.43 (19 |

| 12 – 60 | −40 | ≥27 | ||||

| EVERHARD-C450LE | 6(5) – 11.9 | 450±25 | - | - | ≤0.50 (5≤t≤19) ≤0.53 (19 | |

| 12 – 50.8 | −40 | ≥27 | ||||

| EVERHARD-C500LE | 6(5) – 11.9 | 500±40 | - | - | ≤0.55 (5≤t≤19) ≤0.58 (19 | |

| 2 – 32 | −40 | ≥27 | ||||

| 32.1 – 50.8 | ||||||

| Super Grade | EVERHARD-SP | 6 – 65 | 401min. | - | - | - |

( ) Please inquire for thicknesses shown in parentheses.

* Carbon equivalent Ceq = C+Mn/6+(Cu+Ni)/15+(Cr+Mo+V)/5

In accordance with JIS G3193.

Typical Mechanical Properties of EVERHARD

| Brand name | Thickness (mm) | Mechanical properties | ||||||||||

| Tensile test | Bending test | Charpy impact test | Hardness Test | |||||||||

| Test Specimen | Testing Direction | Yield strength N/mm2 | Tensile strength N/mm2 | Elongation % | Test Specimen | Testing Direction | Bend radius = thickness ×3 | Testing Direction | Absorbed energy vE Average J | Brinell hardness (29.42kN) Average of 5 points | ||

| EVERHARD-C400 | 19 | JIS-5 | T | 1083 | 1246 | 21 | JIS-1 | L | Good | L | 0°C 52 | 404 |

| EVERHARD-C400LE | 19 | JIS-5 | T | 1058 | 1308 | 23 | JIS-1 | L | Good | L | −40°C 61 | 411 |

| EVERHARD-C400LE | 60 | JIS-4 | T | 971 | 1096 | 21 | JIS-1 | L | Good | L | −40°C 189 | 416 |

| EVERHARD-C450 | 19 | JIS-5 | T | 1163 | 1316 | 20 | JIS-1 | L | Good | L | 0°C 48 | 453 |

| EVERHARD-C450LE | 20 | JIS-5 | T | 1121 | 1442 | 19.6 | JIS-1 | L | Good | L | −40°C 45 | 450 |

| EVERHARD-C450LE | 32 | JIS-5 | T | 1106 | 1402 | 24 | JIS-1 | L | Good | L | −40°C 33 | 447 |

| EVERHARD-C450LE | 50 | JIS-4 | T | 1008 | 1290 | 15 | JIS-1 | L | Good | L | −40°C 39 | 469 |

| EVERHARD-C500 | 19 | JIS-5 | T | 1297 | 1449 | 17.7 | JIS-1 | L | Good | - | - | 508 |

| EVERHARD-C500LE | 20 | JIS-5 | T | 1203 | 1681 | 17 | JIS-1 | L | Good | L | −40°C 42 | 502 |

| EVERHARD-SP | 35 | JIS-5 | T | 1104 | 1352 | 10.7 | JIS-1 | L | Good | - | - | 455 |

| EVERHARD-360A | 19 | JIS-5 | T | 1147 | 1203 | 23.9 | JIS-1 | L | Good | L | 0°C 156 | 388 |

| EVERHARD-500A | 20 | JIS-5 | T | 1321 | 1516 | 22.9 | JIS-1 | L | Good | L | 0°C 65 | 542 |

Direction:

Product length: m

| Thickness / Width | 1501 –1800 | 1801 –2000 | 2001 –2200 | 2201 –2400 | 2401 –2600 | 2601 –2800 | 2801 –3000 | 3001 –3200 | 3201 –3400 | 3401 –3600 | 3601 –3800 | 3801 –4000 | 4001 –4200 | 4201 –4400 | 4401 –4600 | 4601 –4800 | 4801 –5000 | 5001 –5200 | 5201 –5300 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 6.0 – 6.9 | 18 | 16 | 14 | 12 | 12 | 10 | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 7.0 – 7.9 | 18 | 16 | 14 | 12 | 12 | 10 | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 8.0 – 8.9 | 18 | 16 | 14 | 12 | 12 | 10 | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 9.0 – 9.9 | 18 | 16 | 14 | 12 | 12 | 10 | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 10.0 – 11.9 | 22 | 20 | 18 | 16 | 14 | 14 | 12 | - | - | - | - | - | - | - | - | - | - | - | - |

| 12.0 – 12.9 | 22 | 20 | 18 | 16 | 14 | 14 | 12 | - | - | - | - | - | - | - | - | - | - | - | - |

| 13.0 – 13.9 | 22 | 20 | 18 | 16 | 14 | 14 | 12 | - | - | - | - | - | - | - | - | - | - | - | - |

| 14.0 – 22.0 | 22 | 20 | 18 | 16 | 14 | 14 | 12 | - | - | - | - | - | - | - | - | - | - | - | - |

| 22.1 – 24.0 | 24 | 22 | 22 | 20 | 18 | 18 | 14 | 12 | - | - | - | - | - | - | - | - | - | - | - |

| 24.1 – 26.0 | 25 | 24 | 22 | 22 | 20 | 20 | 18 | 14 | 12 | - | - | - | - | - | - | - | - | - | - |

| 26.1 – 28.0 | 25 | 25 | 24 | 24 | 22 | 22 | 20 | 18 | 16 | 14 | 12 | - | - | - | - | - | - | - | - |

| 28.1 – 30.0 | 25 | 25 | 25 | 25 | 25 | 25 | 22 | 20 | 20 | 18 | 18 | 16 | 16 | - | - | - | - | - | - |

| 30.1 – 35.0 | 25 | 25 | 25 | 25 | 25 | 25 | 24 | 22 | 22 | 22 | 20 | 20 | 20 | 18 | 18 | 18 | - | - | - |

| 35.1 – 40.0 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 24 | 22 | 22 | 22 | 20 | 20 | 20 | 19 | 18 | - | - | - |

| 40.1 – 45.0 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 24 | 23 | 22 | 20 | 19 | 19 | 18 | 17 | 16 | 16 | - |

| 45.1 – 50.8 | 25 | 25 | 25 | 25 | 25 | 25 | 25 | 23 | 22 | 20 | 20 | 18 | 17 | 17 | 16 | 15 | 15 | 14 | - |

| 50.9 – 60.0 | 25 | 23 | 21 | 24 | 24 | 22 | 20 | 19 | 18 | 17 | 17 | 15 | 14 | 14 | 13 | 12 | 12 | 11 | - |

| 60.1 – 70.0 | 22 | 19 | 18 | 20 | 20 | 19 | 17 | 16 | 15 | 14 | 14 | 13 | 12 | 12 | 11 | 10 | 10 | 10 | - |

| 70.1 – 80.0 | 19 | 17 | 16 | 18 | 18 | 16 | 15 | 14 | 13 | 13 | 13 | 11 | 11 | 10 | 10 | 9.3 | 9.3 | 8.9 | - |

| 80.1 – 90.0 | 17 | 15 | 14 | 16 | 16 | 14 | 13 | 13 | 12 | 11 | 11 | 10 | 9.8 | 9.4 | 8.9 | 8.2 | 8.2 | 7.9 | - |

| 90.1 – 101.6 | 15 | 13 | 12 | 14 | 14 | 13 | 12 | 11 | 10 | 10 | 10 | 9.3 | 8.8 | 8.4 | 8 | 7.4 | 7.4 | 7.1 | - |

Please inquire for maximum product width

| Industry | Applications |

|---|---|

| Construction and Automotive Industries |

|

| Cement and Mining |

|

| Chemical Industry |

|

| Steel and Gas |

|

| Others |

|

EVERHARD plates should be stored so as to avoid bending and twisting. Use waterproof sheets to prevent rust and pitting due to corrosion, which can cause cracking. When using a waterproof sheet, ventilate occasionally to reduce humidity under the sheet.

JFE Steel also provides the EVERHARD with primer (paint) treatment upon request. As a shop primer, JFE normally uses SD ZINC 1000HA (S) manufactured by ALESCO (Kansai Paint Co., Ltd.). This primer consists of modified alkyl silicate binder and zinc (Zn) powder with improved performance. It displays excellent cutting properties and weldability, and also minimizes generation of pitting and blowholes during CO2 gas shielded arc welding. In order to provide this performance, the thickness of the primer layer is strictly controlled within the optimum range.

The following table shows a comparison of conventional EVERHARD series, including the Alloy Series which has been widely used for many years, and the EVERHARD C series.

| Type | Conventional standards (will continue to be available for ordering in future) | EVERHARD C Series | ||||

|---|---|---|---|---|---|---|

| Standard series | Brand name | Thickness (mm) | Brinell hardness [guarantee] (29.42kN) Average of 5 points | Brand name | Thickness (mm) | Brinell hardness [guarantee] (29.42kN) Average of 5 points |

| - | - | - | EVERHARD-C340 | 38 – 160 | 340±30 | |

| EVERHARD-360 | 6(5) – 50.8 | 361min. | EVERHARD-C400 | 6(5) – 101.6 | 400±30 | |

| EVERHARD-360A | 6(5) – 50.8 | |||||

| EVERHARD-400 | 6(5) – 50.8 | 401min. | EVERHARD-C450 | 6(5) – 101.6 | 450±25 | |

| EVERHARD-500 | 6(5) – 50.8 | 477min | EVERHARD-C500 | 6(5) – 101.6 | 500±40 | |

| EVERHARD-500A | 6 – 101.6 | |||||

| - | - | - | EVERHARD-C550 | 6 – 32 | 550±40 | |

| High Toughness series | EVERHARD-360LE | 6(5) – 60 | 400− +40 39 | EVERHARD-C400LE | 6(5) – 60 | 400±30 |

| EVERHARD-400LE | 6(5) – 50.8 | 450±40 | EVERHARD-C450LE | 6(5) – 50.8 | 450±25 | |

| EVERHARD-500LE | 6(5) – 32 | 500− +56 23 | EVERHARD-C500LE | 6(5) – 50.8 | 500±40 | |

( ) Please inquire for thicknesses in parentheses