Listing ID #4019114

Company Information

Ask for more detail from the seller

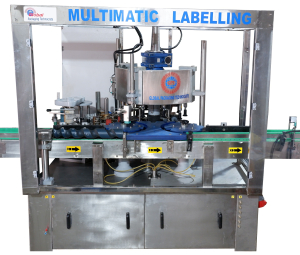

Contact Supplier| Direction of Movement | Left to Right | |

| Output per Hour | 3600 to 9000 Nos. Depending on container Size andLabel Size. | |

| Electrical | Main Motor | 0.75 HP / 415 Volts / 50 Hz. |

| Specification | Vaccum pump | 0.5 HP / 415 Volts / 50 Hz. |

| Height of Conveyour- | 860 mrn to 910 mm | |

| Machine Dimension- | 3000 mm (L) x 1016 mm (W) x 1170 (H) mm | |

| Gross Weight | 700 kgs | |

| Change Parts Required | (A) Container: Feed Worm | |

| (B) Label : Label Muster, Upper - Lower Plate, Pusher Plate | ||

| INPUT SPECIFICATION | ||

| Length | 20 mm to 140 mm | |

| Label | Height | 16 to 90 mm |

| Ø16 mm to Ø 100 mm | ||

| Container | Round Shape | Respectively Height 40mm x 240 mm (Height option for other bottle height available |

| size | ||