Listing ID #3698435

Company Information

Ask for more detail from the seller

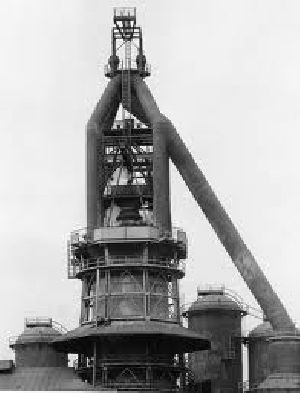

Contact SupplierBlast Furnace Slag is a by-product from the manufacturing of steel in a blast furnace. Initially in its molten form, it is diverted to a granulator where it is quenched with water and rapidly cooled to form glassy, non-metallic granules which are silicates and aluminosilicates of calcium. These granules are dried to produce Granulated Blast Furnace Slag (GBFS).Due to stringent quality control in the steel production process, the chemical composition of its by-product GBFS is highly stable. Regular checks are carried out on the granulate to monitor the amount of glass produced as a control on the effectiveness of the quenching process. GBFS is light in color, around 3mm down to dust in size and has a relatively high moisture content. The material is allowed to drain by stocking in heaps for sufficient time.GBFS is ground to a suitable fineness to produce Ground Granulated Blast Furnace Slag (GGBFS), which is used as a cementitious material in concrete to enhance long-term performance and durability characteristics while reducing life-cycle and maintenance costs. With the poor quality, contamination (silt, clay, etc.) and depletion of natural sand, as well as significant negative environmental impact of crushed sand (rockgranite), GBFS has found its way as an effective replacement of natural sand crushed sand in concrete as a fine aggregate. Advantages include reduction of cement content, higher reactive silica and negligible silt content, improved strength, reduced permeability and chemical attacks, increased durability, lower shrinkage cracks, better cohesiveness and workability, improved bonding and smoother finish.