Listing ID #4372818

Company Information

Ask for more detail from the seller

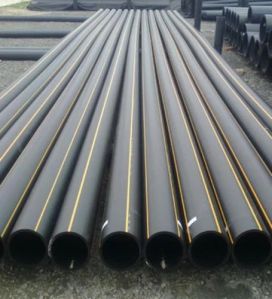

Contact SupplierThese materials are the most appropriate replacement for CI pipes and GI pipes and are one of the most premier mediums of conveying and transporting,

• Gases

• Portable water

• Chemicals

• Telecommunication and electrical ducting

• Drip irrigation systems

• Sprinkler systems

Advantages of using HDPE ducts or polyethene pipes:

• The first and foremost advantage of using HDPE pipes is that these conduits are as much as 6 to 8 times lighter than the CI popes and the GI pipes.

• Secondly, the HDPE pipes are exceptionally easy to carry which saves upon the transportation costs and also helps keep the handling costs at a lower level.

• Thirdly, the HDPE pipes and conduits are often available in handy straight lengths of 5 to 6 meters or coils of 50 meters to 200 meters. This helps minimize the number of joints also easing the process of lying out. With the coils and the straights, it becomes a lot easier and quicker to lay the HDPE pipes.

• The HDPE pipe and fittings and the high-density polyethene pipes are essentially non-corrosive which makes them appropriately suitable for the purpose of water transportation.

• As far as the transferring of heat goes, the rate of energy transfer is a lot low in the HDPE conduits and pipes.

• The HDPE pipes essentially have a smoothened out inner surface that hinders the growth of bacteria and microorganisms of any kind. This ensures that the pumping process remains faster and smoother and requires the least amount of effort.

Various kinds of uses procured by polyethene pipes and HDPE ducts include:

• One of the prime uses served by the high-density polyethene pipes is to supply drinking water.

• The flexible HDPE pipes and telecom duct polyethene pipes are used for serving as telecom ducts.

• Serving for irrigation is yet another significant purpose that makes use of large quantities of HDPE pipes and fittings and HDPE ducts.

• Hdpe pipes and conduits are also used for serving with the sprinkler irrigation systems.

• The HDPE pipes and fittings also comprise a very significant part of the drip irrigation systems as well.

• The non-corrosive nature of the HDPE pipes makes them more than suitable for sewerage and sewage disposal.