Listing ID #3802015

Company Information

Ask for more detail from the seller

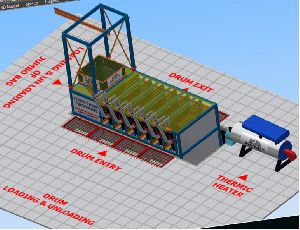

Contact SupplierCapious Bitumen Decanters and Drum Melters are primarily used with asphalt mixing plants in territories where bitumen in bulk is either not available or irregular supplies bitumen stored in drums is used as an alternative.

Capious Bitumen decanters are designed for very easy to operate, low man power and provide the most efficient system for ensuring a high throughput of drummed bitumen. Designed for use in association with bulk storage tanks the melted bitumen is automatically transferred from the decanter storage tank to the Bitumen bowser or bitumen tank during the decanting process.

We have two models available with a melting rate of about 4 and 6 ton/hour. This equipment is designed to continuously melt bitumen contained in standard drums of 200 kg/each, so to enable a constant supply of bitumen. If needed, a suitable hot oil heater should be provided.

It is a continuous drum feeding type melter and not a batch type. Drums are continuously loaded / pushed into heating chamber by a hydraulic system. The unit consists of two parts upper is a melting chamber & lower part is Storage tank for melt bitumen Drums are heated in an enclosed well insulated chamber by circulating hot oil of 200 deg. C temp through many heating coils made of seamless tubes. The drums pass through a bank of such coils and so gets heated in a few minutes only and drains into an underneath storage tank. Melt bitumen in this storage tank is also heated to a desired temp. by same type of heating coils. The hot bitumen from this tank is then pumped out by a positive displacement type gear pump with jacketed body In heating chamber, drums are arranged in Two / Three rows and pushed further on rails up to end till bitumen melts completely and empty drums are exiting from rear doors of equipment in continuous mode, The unit is available stationary Type / Mobile type The melting capacity of 4 tph to 6 tph maximum Entire body of unit is well insulated with a thick glass wool with G.I./ Aluminium / S. S sheet cladding.