Listing ID #454813

Company Information

Ask for more detail from the seller

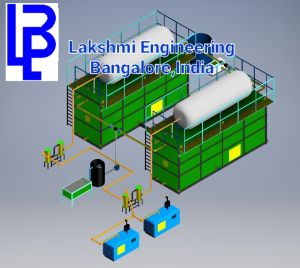

Contact SupplierWe are offering Biogas Upgrading Plant- Pressurized Water Scrubbing Process.

Pressurized water scrubbing process has been found as most efficient and convenient process to upgrade raw bio gas.

the upgrading system treats raw bio gas through the removal of co2, h2s, siloxanes and other soluble gases to produce primarily methane gas (~ 97-98%) which is clean and dry. The gas process comprises of gas compression,gas upgrading, gas drying & purifying operations and can be filled directly in high pressure bullets for distribution purpose.

The bio gas compression system compresses the raw bio gas to a pressure suitable for processing. The system consists of a scrubbing vessel for water scrubbing (absorption of co2 and other soluble gases into water), a flashing vessel for methane recovery and a stripping vessel for regeneration of the process water. The drier/purifying system dries & polishes the upgraded gas after the scrubbing vessel making it suitable for use as a vehicle fuel or for pipeline injection. The system eliminates virtually all h2s from the product gas.

key features and benefits: system with patented technology achieves methane gas dew point of -80°c; compressed to 250 bar (g). Ppb (part per billion)level of hydrogen sulphide (h2s) and thus eliminating corrosive gas to minimize environmental effects.

Reliability& energy-efficient: negligible maintenance parts means less down time, high reliability and lower overall operating costs with our rotary compressors unlike reciprocating compressors.offers the highest methane gas production to energy utilisation ratio.

Utilities: system offers low utilities consumption – important where water resources and effluent disposal is a concern.

Rugged material & design: process vessels and pipes with bio gas and water contact are fabricated from stainless steel 316/316l, or grp (glass reinforced plastic).

Remote management :web-based monitoring and diagnostic reporting from anywhere in the world is provided, coupled with full service contract options. This makes preventative maintenance effective, resulting in high availability and reliable operation.

Energy recovery: recoverable heat can be up to 90% of the compressors main drive motor which is ideal for digester heating. Up to 15% of the power required by the water pump is also recovered as standard on larger systems.

Standard plant capacity:

flow nm3/hr 80 130 300 800 1200 2000

electricity 25 41 81 207 291 407 consumption

kw

water 0.2 0.32 0.72 2.0 2.9 4.8 consumption

per day, m3