Listing ID #4008667

Company Information

Ask for more detail from the seller

Contact Supplier

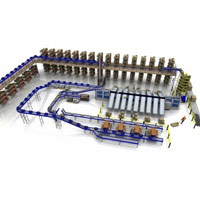

Our conveyor belts have quality and features matching international standards and are optimised to meet specific requirements. The conveyor support frame is made of structural steel and transom is made of MS sheet with high precision laser cut CNC-bent profile and galvanized for rust protection and long life. The head and tail pulley drums are statically balanced. The drive pulley has a diamond patterned rubber friction lining. The troughing arrangement of the belt is two-roller type. The rubber belt for the conveyors is EP 400/3. The drive of the conveyor belt includes a helical bevel reduction gearbox and a motor. The front segment scraper is an adjustable type unit for positive pressure on the belt surface with scraper blades. The internal scraper is V-shaped structural frame with a rubber strip. For safe operation, suitable safety covers are provided around geared motors / drums and the rotating equipment on either side of the conveyor with pull chord switch arrangement at one side for emergency stop.