Listing ID #3618249

Company Information

Ask for more detail from the seller

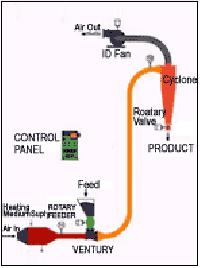

Contact SupplierCopra (Batch type) dryers are used for drying raw coconuts in one lot as a batch. The raw coconut pieces along with their shells are loaded in a chamber over a platform having perforated sheet or weld mesh bottom to permit easy flow of hot air through materials. The hot air is blown into the plenum chamber below the platform by the powerful blower of the hot air generator and it passes through the coconuts extracting moisture from it. The moisture escapes through the opening on the top of chamber. Batch type dryers are very popular in India for making high quality edible white copra from well matured coconuts. It is approved by the Coconut Development Board of India. The copra making time is reduced to 24 hours of drying instead of usual 5 or 6 days by sun drying - The fuel used for drying can be coconut shell which is a By-Product in copra making or any other normal fuel like copra shell, coconut fibre, electricity, firewood etc. As the hot air generator of dryer has a heat exchanger, it removes smoke and flue gas and only pure hot air is used for drying. Hence the quality of dried product is very high. The dried coconuts are scooped from their shell and are passed for cutting after 36 hours of heating in Drier.