Listing ID #3817069

Company Information

Ask for more detail from the seller

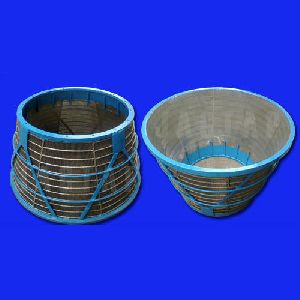

Contact SupplierThe horizontally arranged MBE CMTI vibrating Screen Basket Centrifuge, the material to be dewatered is fed into the inlet cone through the feed pipe. While flowing through the inlet cone, the material is slowly accelerated and uniformly distributed on the circumference of the slot type Screen Basket. The rotating basket is made to perform axial vibration by a vibrator unit with unbalanced drive.

Due to the combination of Centrifugal & Vibratory components, these axial vibrations have the material transported inside the conical screen basket along the inclined basket will. This movement entails a reduced friction between the feed & basket wall.

The Centrifuge is mounted on Rubber Buffers for preventing the transmission of vibrations to the foundation. Vibration may occur as a result of fluctuating feed rates.

The horizontal design permits fitting the drive components to the outside of the machine housing. This means that all drive parts and consequently the basket inside the machine housing is easily accessible. The one piece Screen Basket and the inlet cone have been fastened to the Basket Shaft in an overhung position by means of the load bearing ring. This ensures easy assembly & dismantling. The vibrator with out of balance weight is accommodated in the bearing housing of the basket shaft. The complete drive mechanism has been suspended by the guide linkage spring. The axial vibrations are transmitted to the screen basket direct on the basket shaft and the load bearing ring without resilient element having been interposed. This results in a very simple & robust design. The vibrating mass is made up of the Screen Basket, Inlet cone, Load Bearing Ring & Basket Shaft as well as of the drive mechanism. It exceeds by further mass of material accumulating. Due to this fact and the horizontal arrangement, the centrifuge is insensitive towards the overload or fluctuating feed rates. The Screen Basket & Vibrator are each driven by a standard motor and V Belt.The MBE Basket Centrifuge is particularly suitable for continuous separation of solid/ liquid mixtures of grainy bulk materials. The standardized design of mechanical & Centrifugal components enables optimum adaption to the specific requirement. Details of this standardized design, of the dewatering process & design criterion have been given on the following pages.

Coal Fines

• Fine Tailings

• Coarse Slurry

• Washed Coal & middling

• Fine Gravel

• Sand

• Potash dissolving residue

| Parameter | Type F | Type G | Type H |

| Machine Dimension (M) | 1.8 x 2.4 x 1.45 H | 2.3 x 2.7 x 1.9 H | 2.3 x 2.8 x 1.9 H |

| Weight (T) | 3.4 | 4.8 | 5.3 |

| Basket diameter (M) | 1 | 1.15 | 1.3 |

| Basket Inclination (deg.) | 10/12/14 | 10/12/14 | 10/12/14 |

| Lubrication | Circulating Oil | Circulating Oil | Circulating Oil |

| Amplitude (mm) | 01/05/03 | 01/05/03 | 01/05/03 |

| Solid Recovery | 97-99% | 97-99% | 97-99% |

| Dewatering | 5-9% | 5-9% | 5-9% |